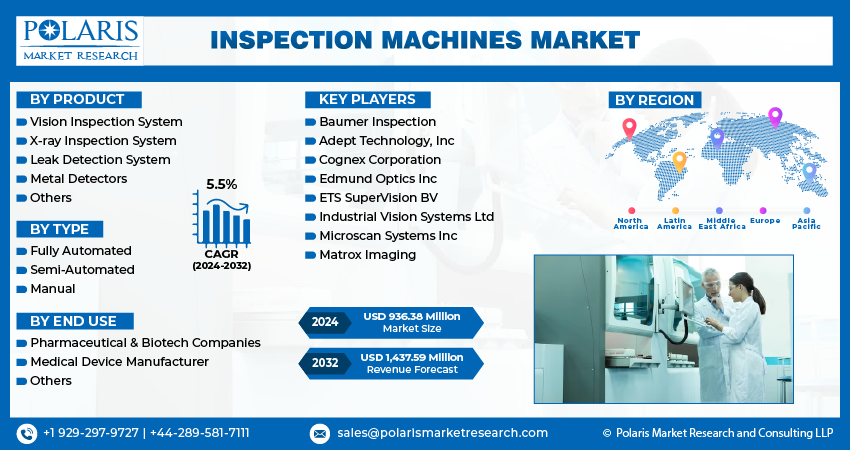

The global inspection machines market size is expected to reach USD 1,437.59 million by 2032, and it is anticipated to develop at a compound annual growth rate (CAGR) of 5.5%.

The inspection machines market refers to the industry dedicated to the design, development, and supply of automated machines used for inspecting, testing, and ensuring the quality and safety of products across various industries. These machines play a critical role in detecting defects, measuring product characteristics, and ensuring that goods meet quality standards before reaching consumers. The market is characterized by a wide range of inspection technologies, such as vision inspection, X-ray inspection, metal detectors, and other non-destructive testing (NDT) systems.

𝐆𝐞𝐭 𝐄𝐱𝐜𝐥𝐮𝐬𝐢𝐯𝐞 𝐒𝐚𝐦𝐩𝐥𝐞 𝐏𝐚𝐠𝐞𝐬 𝐨𝐟 𝐓𝐡𝐢𝐬 𝐑𝐞𝐩𝐨𝐫𝐭:

Market Overview

Inspection machines are used in industries such as pharmaceuticals, food & beverage, automotive, electronics, packaging, and many others. With the rise in demand for high-quality, safe products, the market for these machines has experienced substantial growth. Automation in manufacturing processes and the increasing need for regulatory compliance have further bolstered the market. The growing demand for inspection machines is driven by technological advancements, including artificial intelligence (AI) and machine learning, which have enhanced the capabilities of inspection systems to detect more complex defects with higher precision.

The global inspection machines market is expected to continue expanding due to the increasing adoption of automated systems, advancements in machine vision and inspection technologies, and the growing importance of quality assurance across industries.

Competitive Insight

Some of the major players operating in the global inspection machines market include

- Baumer Inspection,

- Adept Technology, Inc,

- Cognex Corporation,

- Edmund Optics Inc,

- ETS SuperVision BV,

- Industrial Vision Systems Ltd,

- Microscan Systems Inc,

- Matrox Imaging, etc.

Market’s Growth Drivers

- Technological Advancements: The development of advanced inspection technologies, such as AI-powered vision systems, X-ray machines, and robotics, has greatly improved inspection accuracy, speed, and cost-efficiency. These technologies can detect defects that are difficult to identify with traditional methods, offering greater precision and reducing human error.

- Increasing Demand for Quality Assurance: In sectors like food, pharmaceuticals, and automotive, ensuring the quality and safety of products is essential. Regulatory bodies across the globe are implementing stricter guidelines to guarantee product safety, driving the need for reliable inspection systems.

- Automation and Industry 4.0: The growing trend of automation and the integration of Industry 4.0 technologies in manufacturing processes are accelerating the use of inspection machines. These systems help reduce the need for manual inspection, improve operational efficiency, and allow real-time monitoring of production lines.

- Rising Consumer Expectations: As consumers demand higher quality and more consistent products, manufacturers are under increasing pressure to meet these expectations. Inspection machines help companies maintain product standards by identifying defects early in the production process.

- Globalization of Supply Chains: With global supply chains becoming more interconnected, there is a greater focus on maintaining high product quality across borders. Inspection machines facilitate quality control, especially for manufacturers who need to comply with international standards and regulations.

𝐒𝐞𝐠𝐦𝐞𝐧𝐭𝐚𝐥 𝐀𝐧𝐚𝐥𝐲𝐬𝐢𝐬:

The research study includes segmental analysis that divides the market into distinct groups or segments based on common characteristics. With market segmentation, businesses can identify specific customer groups that are more likely to be interested in specific products or services. Also, it enables these businesses to focus their marketing efforts and resources more efficiently, leading to higher conversion rates and improved return on investment. Furthermore, segmentation analysis helps companies develop personalized products or services, which can result in increased customer loyalty and improved customer satisfaction.

Inspection Machines Market, Product Outlook (Revenue – USD Million, 2019-2032)

- Vision Inspection System

- X-ray Inspection System

- Leak Detection System

- Metal Detectors

- Others

Inspection Machines Market, Type Outlook (Revenue – USD Million, 2019-2032)

- Fully Automated

- Semi-Automated

- Manual

Inspection Machines Market, End Use Outlook (Revenue – USD Million, 2019-2032)

- Pharmaceutical & Biotech Companies

- Medical Device Manufacturer

- Others

Key Trends in the Inspection Machines Market

- Integration with Artificial Intelligence and Machine Learning: AI and machine learning are enabling inspection systems to continuously learn and adapt, improving their ability to identify defects and anomalies. These technologies allow for more complex, faster, and efficient inspections, leading to better product quality assurance.

- Robotic Automation: The incorporation of robots with inspection machines is a growing trend. Robots are used to handle products on production lines while inspection systems scan for defects, reducing human intervention and improving efficiency.

- Miniaturization and Compact Designs: As industries push for smaller, more versatile machines, inspection systems are being developed with more compact designs that fit into smaller manufacturing spaces without compromising performance.

- Real-Time Data Collection and Analytics: Inspection machines are increasingly being equipped with data collection and analytics capabilities. This allows manufacturers to track product quality and performance metrics in real time, which enhances decision-making and facilitates predictive maintenance.

- Non-Destructive Testing (NDT): Non-destructive inspection techniques, such as ultrasonic testing, X-ray, and laser-based systems, are growing in demand. These methods allow for thorough inspections without damaging the product, particularly important in industries like aerospace and automotive.

Research Scope

The research scope in the inspection machines market spans multiple aspects, including the development of new inspection technologies, the integration of AI and machine learning, and the expansion of automated systems. Market research typically covers the key types of inspection machines (vision inspection, X-ray inspection, metal detectors, etc.), industry applications (food and beverage, pharmaceuticals, automotive, etc.), geographical regions (North America, Europe, Asia-Pacific, etc.), and market dynamics such as trends, challenges, and opportunities.

Emerging trends like the digitalization of the manufacturing process, smart factories, and the rise of Industry 4.0 are also key areas of research. Studies often focus on understanding how these innovations impact the market growth, the adoption rates across industries, and how companies are leveraging these technologies to enhance inspection systems.

Future Scope

The future of the inspection machines market looks promising as industries continue to embrace automation and technological advancements. Several key areas are expected to drive future growth:

- AI and IoT Integration: As artificial intelligence and the Internet of Things (IoT) continue to evolve, their integration into inspection machines will enable smarter, real-time monitoring, predictive maintenance, and more efficient quality control systems.

- Adoption in New Industries: While the food, automotive, and pharmaceutical sectors are currently the biggest adopters of inspection machines, emerging industries such as electronics, textiles, and renewable energy will likely see increased demand for quality control solutions in the coming years.

- Sustainability Focus: With increasing focus on sustainability, inspection machines will be increasingly designed to minimize energy consumption and reduce waste. Additionally, manufacturers will seek inspection solutions that help optimize material usage and reduce production defects.

- Customization and Flexibility: The demand for customized inspection machines that can be tailored to specific production needs is expected to rise. Flexibility in machine design and capability will be critical for manufacturers that work with diverse product types and production lines.

- Growing Demand for Safety and Compliance: As regulatory frameworks continue to tighten across industries, especially in pharmaceuticals, food, and automotive sectors, the demand for inspection machines that ensure compliance with safety and quality standards will grow significantly.

Recent Developments

- In January 2022, Ishida introduced the IX-G2-F x-ray inspection system, featuring enhanced sensitivity. The system incorporates a new line sensor that delivers high-quality x-ray images with an improved signal-to-noise ratio.

Quality and safety are of paramount importance in various industries, especially in critical sectors such as pharmaceuticals and medicine. Along with the purity of active ingredients and adherence to stringent regulations, the health of patients depends on the quality of packaging and storage products like vials, bottles, and ampoules. Inspection machines are machines that are primarily used to ensure the quality of packaging items in the pharmaceutical, biotechnology, and medical device manufacturing industries. These machines rely on state-of-the-art technology and special configurations to determine whether the products meet the standards and regulations.