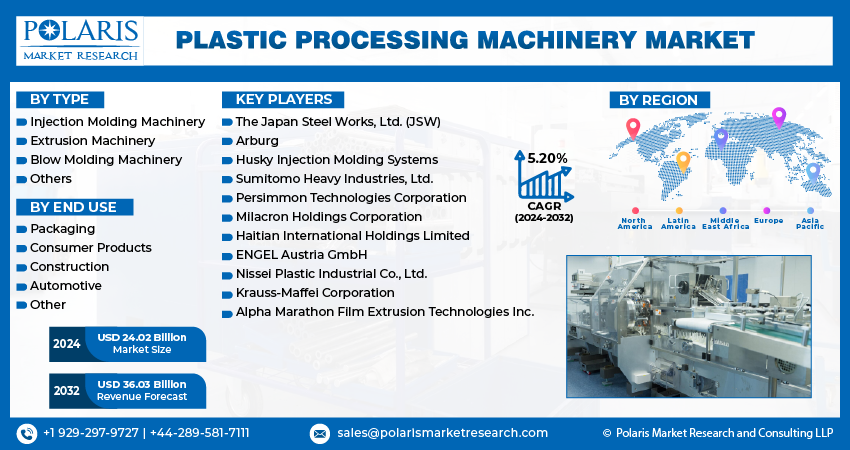

The plastic processing machinery market is projected to reach a value of $36.03 billion by 2032, growing at a CAGR of 5.20% from 2023 to 2032. These machines play a pivotal role in transforming raw plastic materials into finished products for a wide range of industries, including automotive, packaging, construction, electronics, and healthcare. The increasing demand for plastic components in various applications, coupled with advancements in manufacturing technologies, is driving the growth of the market.

Download Free Sample PDF Copy of the Report:

Key Drivers of Market Growth

- Rising Demand for Plastic Components: Plastic materials are lightweight, durable, and cost-effective, making them ideal for use in a wide array of industries. The growing demand for plastic components, especially in packaging, automotive, and consumer goods, is fueling the need for advanced plastic processing machinery.

- Technological Advancements: Innovations in plastic processing machinery, such as the development of automated systems, digital controls, and integration with artificial intelligence (AI), are improving the efficiency and precision of manufacturing processes. These technological advancements help manufacturers optimize production, reduce waste, and enhance product quality, driving the adoption of these machines.

- Sustainability and Recycling Efforts: With increasing environmental awareness, there is a growing emphasis on recycling and sustainable plastic production. Plastic processing machinery that supports recycling processes, such as extrusion and injection molding, is gaining popularity. This shift towards more sustainable manufacturing methods is driving demand for machines that can handle recycled plastic materials effectively.

- Growth in End-User Industries: The automotive, packaging, electronics, and construction industries are major consumers of plastic products. As these sectors continue to grow, the demand for plastic processing machinery also increases. The push for lightweight automotive parts, for example, is a significant contributor to the growing need for plastic processing technologies.

Market Growth and Opportunities

The plastic processing machinery market is expected to witness substantial growth in the coming years. Key factors driving this growth include:

- Expansion of the Packaging Industry: The packaging sector is one of the largest consumers of plastic, driven by the increasing demand for consumer goods. Flexible packaging solutions, which often require advanced plastic processing machinery, are gaining traction in various industries, from food and beverage to pharmaceuticals.

- Automotive Industry Developments: As the automotive industry shifts toward electric vehicles (EVs), there is a growing need for lightweight materials, including plastic. Plastic processing machinery plays a vital role in the production of automotive components such as bumpers, dashboards, and interior trims, which is contributing to the growth of the market.

- Emerging Markets: Developing regions such as Asia-Pacific, Latin America, and the Middle East are witnessing significant industrialization, which is increasing the demand for plastic products. These regions represent lucrative opportunities for manufacturers of plastic processing machinery.

- 3D Printing and Additive Manufacturing: The rise of 3D printing and additive manufacturing technologies has opened new avenues for plastic processing. These technologies allow for the production of highly customized plastic components, creating opportunities for the development of specialized plastic processing machinery.

Key Trends in the Market

- Automation and Smart Manufacturing: Automation is revolutionizing plastic processing, making production lines more efficient and cost-effective. Automated plastic processing machinery, equipped with sensors, robotics, and artificial intelligence, is enabling faster and more accurate manufacturing. Smart factories are becoming more common, where machinery is integrated into the industrial internet of things (IIoT) to enable real-time monitoring and predictive maintenance.

- Focus on Energy Efficiency: As energy costs rise and sustainability becomes a top priority, plastic processing machinery manufacturers are focusing on improving the energy efficiency of their machines. Energy-efficient machines help reduce operational costs, making them attractive to manufacturers who are looking to optimize their energy consumption and reduce their environmental impact.

- Customization and Versatility: Manufacturers are increasingly looking for versatile plastic processing machinery that can handle a wide range of materials and produce a variety of plastic components. The ability to customize machines to meet specific production requirements is becoming a key trend in the market, especially as industries seek to diversify their product offerings.

- Growth of Bioplastics: Bioplastics, made from renewable resources like corn starch or sugarcane, are gaining popularity due to their environmentally friendly properties. Plastic processing machinery that can handle bioplastics, alongside traditional plastics, is increasingly in demand as the shift toward more sustainable materials grows.

Challenges in the Plastic Processing Machinery Market

- High Capital Investment: The initial cost of plastic processing machinery can be substantial, especially for advanced machines with automation, robotics, or smart features. Small and medium-sized enterprises (SMEs) may find it challenging to justify the investment, which could limit the adoption of these machines.

- Skilled Labor Shortage: Operating and maintaining advanced plastic processing machinery requires skilled technicians. The shortage of trained personnel in some regions could pose a challenge to market growth, as manufacturers may face difficulties in ensuring the smooth operation of their machinery.

- Volatility of Raw Material Prices: The prices of raw materials like petroleum (a key input for plastic production) are highly volatile. Fluctuations in raw material costs can affect the production cost of plastic components, which could, in turn, impact the demand for plastic processing machinery.

Market Opportunities

- Expanding Recycling Capabilities: The demand for recycled plastic is rising as industries strive to reduce their environmental footprint. Plastic processing machinery that is capable of processing recycled materials offers a significant opportunity for manufacturers, especially in industries like packaging, automotive, and construction.

- Emerging Applications of Plastic in Healthcare: The healthcare industry is increasingly relying on plastics for the production of medical devices, packaging, and surgical tools. This offers a new growth opportunity for plastic processing machinery that can meet the stringent regulatory and quality standards of the healthcare sector.

- Technological Innovations and Upgrades: Manufacturers have the opportunity to capitalize on the growing trend of technological innovation. By offering state-of-the-art, high-performance machines that incorporate the latest advancements, companies can gain a competitive edge in the rapidly evolving plastic processing machinery market.

Top Companies:

Understanding key players and their initiatives provides valuable insights into the competitive landscape and emerging opportunities in the market. Here are the top companies in the market:

- The Japan Steel Works, Ltd. (JSW)

- Arburg

- Husky Injection Molding Systems

- Sumitomo Heavy Industries, Ltd.

- Persimmon Technologies Corporation

- Milacron Holdings Corporation

- Haitian International Holdings Limited

- ENGEL Austria GmbH

- Nissei Plastic Industrial Co., Ltd.

- Krauss-Maffei Corporation

- Alpha Marathon Film Extrusion Technologies Inc.

Country-Wise Insights:

- North America

- U.S.

- Canada

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Netherlands

- Asia Pacific

- China

- India

- Japan

- South Korea

- Indonesia

- Malaysia

- Latin America

- Argentina

- Brazil

- Mexico

- Middle East & Africa

- UAE

- Saudi Arabia

- Israel

- South Africa

The plastic processing machinery market is set for robust growth, driven by the increasing demand for plastic products, technological advancements, and the expansion of key end-user industries like automotive, packaging, and healthcare. While challenges such as high capital costs and the need for skilled labor remain, the market presents numerous opportunities, particularly in the areas of sustainability, recycling, and automation. Companies that embrace innovation and adapt to changing market demands will be well-positioned to capitalize on the growing demand for plastic processing solutions in the years to come.