Market Overview

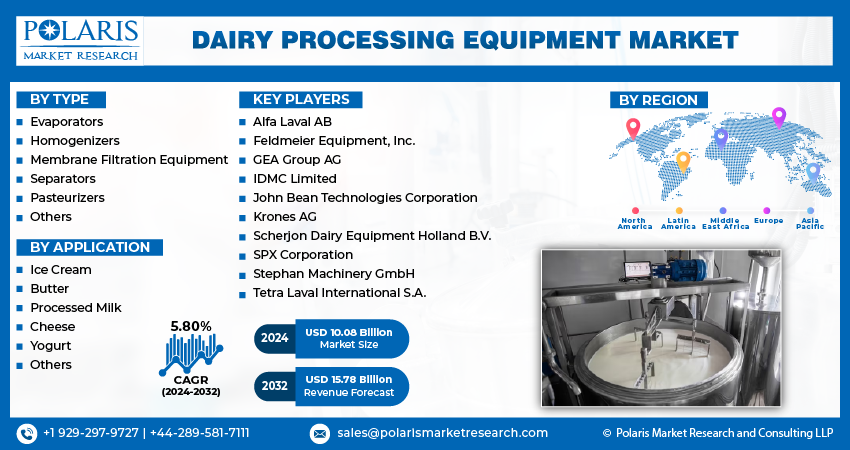

The global dairy processing equipment market was valued at USD 9.58 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.80% from 2024 to 2032. Dairy processing equipment includes machines and systems used for the processing of milk and other dairy products, such as cheese, butter, yogurt, and ice cream. These technologies are crucial in transforming raw milk into a wide range of consumable products by applying methods like pasteurization, homogenization, fermentation, and packaging.

As the dairy industry continues to evolve with changing consumer demands, innovations in dairy processing equipment play a pivotal role in enhancing product quality, optimizing production efficiency, and ensuring food safety. Factors such as rising global demand for dairy products, advancements in technology, and the growing emphasis on automation in the food processing industry are driving the growth of this market.

Key Market Drivers

- Increasing Demand for Dairy Products

The global demand for dairy products, including milk, cheese, yogurt, and ice cream, continues to rise due to population growth, urbanization, and changing dietary patterns. As more consumers incorporate dairy into their daily diets, the demand for efficient and high-quality dairy processing equipment grows correspondingly. - Technological Advancements in Dairy Processing

Technological innovations in dairy processing equipment, such as automated systems, real-time monitoring, and energy-efficient machines, are making dairy production more efficient. These advancements improve the quality of products, reduce production costs, and enhance food safety, making the market for such equipment increasingly attractive to manufacturers. - Rising Focus on Food Safety and Quality

With increasing concerns about food safety, regulations around dairy production have become stricter. Dairy processing equipment plays a key role in ensuring compliance with these safety standards. Advanced systems help prevent contamination, maintain product quality, and ensure that dairy products are safe for consumption, which is essential in maintaining consumer trust and meeting regulatory requirements. - Shift Toward Automation

The shift toward automation in food production processes, including dairy processing, is one of the key drivers of the market. Automated systems reduce the need for manual labor, lower operational costs, and enhance production efficiency. Additionally, automation allows for greater consistency and precision in the processing of dairy products, which is vital for meeting consumer demands for high-quality products. - Sustainability and Energy Efficiency

With sustainability becoming a significant global focus, the dairy processing industry is shifting toward energy-efficient and environmentally friendly technologies. Equipment that uses less water, energy, and packaging materials is gaining popularity, as it helps reduce the overall environmental footprint of dairy production. Furthermore, manufacturers are increasingly integrating renewable energy sources into their dairy processing plants, further driving the demand for advanced equipment.

Key Players in the Dairy Processing Equipment Market

The dairy processing equipment market is competitive, with numerous global and regional players involved in the manufacturing and supply of specialized machinery. Key players include:

- Alfa Laval

- GEA Group

- SPX FLOW

- Tetra Laval

- Krones AG

- IDMC Ltd.

- JBT Corporation

- DairyTech Inc.

- Fenco Food Machinery

These companies are focusing on innovation, product quality, and expanding their geographical presence through strategic partnerships and acquisitions.

𝐄𝐱𝐩𝐥𝐨𝐫𝐞 𝐓𝐡𝐞 𝐂𝐨𝐦𝐩𝐥𝐞𝐭𝐞 𝐂𝐨𝐦𝐩𝐫𝐞𝐡𝐞𝐧𝐬𝐢𝐯𝐞 𝐑𝐞𝐩𝐨𝐫𝐭 𝐇𝐞𝐫𝐞:

https://www.polarismarketresearch.com/industry-analysis/dairy-processing-equipments-market

Market Growth and Trends

Several key trends are influencing the dairy processing equipment market and contributing to its rapid growth:

- Health and Wellness Trends

Consumers are increasingly seeking healthier alternatives, which has led to a rise in demand for low-fat, low-sugar, and probiotic-enriched dairy products. This trend is driving the need for advanced processing equipment that can produce specialty dairy items such as Greek yogurt, lactose-free milk, and fortified cheeses. The growing interest in plant-based alternatives (such as oat, almond, and soy milk) is also creating opportunities for dairy processing equipment manufacturers to innovate and cater to the diverse needs of consumers. - Adoption of Smart Technology

The dairy industry is embracing the use of smart technologies, including the Internet of Things (IoT), artificial intelligence (AI), and machine learning (ML), in processing equipment. These technologies allow for real-time monitoring of the production process, predictive maintenance of equipment, and enhanced efficiency. Smart dairy processing equipment can also optimize energy use and ensure better resource management, which is becoming increasingly important in the context of rising energy costs and environmental concerns. - Growing Popularity of Dairy-based Functional Foods

Functional dairy products, such as probiotic yogurt, fortified milk, and cheese, are becoming more popular due to their health benefits. These products are gaining traction among consumers who are looking for added nutrition in their diets. This trend is driving the need for specialized dairy processing equipment capable of producing these functional foods with enhanced shelf life, taste, and nutrient retention. - Global Expansion of Dairy Processing Facilities

With growing demand for dairy products in emerging markets, especially in Asia Pacific, manufacturers are setting up new dairy processing facilities or expanding existing ones. This trend is leading to an increased demand for dairy processing equipment as companies aim to meet local consumer preferences and adhere to regional food safety regulations.

In-depth Market Segmentation

To understand the dairy processing equipment market more thoroughly, it can be segmented based on type, application, and region.

- By Type of Equipment

- Pasteurizers: These are essential for heating milk and other dairy products to a specific temperature to kill harmful bacteria and prolong shelf life. Pasteurization is a critical step in dairy processing to ensure safety and product quality.

- Homogenizers: Homogenization helps in breaking down fat molecules in milk to create a smooth and consistent texture. Homogenizers are vital for producing products such as milk, cream, and yogurt.

- Separators: Separators are used to separate cream from milk, which is crucial for producing various dairy products like butter and cream.

- Cheese Making Equipment: This includes equipment used in the production of different cheese varieties, such as curdling machines, molders, and cutters.

- Evaporators and Dryers: These are used to remove water content from dairy products, producing concentrated milk or milk powder, which is essential for the production of infant formula and other dairy-based products.

- Filling and Packaging Equipment: These machines are responsible for filling and packaging dairy products in containers, ensuring product safety, hygiene, and shelf life.

- By Application

- Milk Processing: This involves the processing of raw milk into a variety of products, including pasteurized milk, cream, and milk powder.

- Cheese Processing: Dairy processing equipment is widely used in the production of various cheese types, including soft, hard, and processed cheeses.

- Butter and Cream Processing: Equipment used in this category is essential for separating cream from milk and then processing it into butter or other cream-based products.

- Yogurt Processing: Yogurt processing equipment includes machinery for fermentation, cooling, and packaging, which ensures high-quality and nutritious yogurt.

- Ice Cream Processing: This includes machines that mix, freeze, and package ice cream products.

- By Region

- North America: North America is one of the largest markets for dairy processing equipment, driven by high dairy consumption rates, a well-established dairy processing industry, and continuous technological innovations in the region. The U.S. and Canada are major contributors to the market.

- Europe: Europe is a key market for dairy processing equipment due to the presence of well-established dairy manufacturers and a large consumer base for dairy products. The demand for automation and energy-efficient equipment is strong in the region.

- Asia Pacific: The Asia Pacific region is expected to witness the highest growth in the dairy processing equipment market, driven by the increasing demand for dairy products in emerging economies like China, India, and Southeast Asia. The rise of middle-class populations, urbanization, and the growing preference for dairy-based foods are contributing to this growth.

- Latin America: The demand for dairy products in Latin America is rising, leading to increased investment in dairy processing equipment. Brazil and Mexico are the leading markets in the region.

- Middle East and Africa: The Middle East and Africa are experiencing steady growth in the dairy processing equipment market due to rising dairy consumption and an increase in dairy production facilities.

Conclusion

The dairy processing equipment market is set for strong growth, driven by technological advancements, increasing consumer demand for dairy products, and the need for more efficient and sustainable production processes. As the industry continues to evolve, dairy processors will increasingly rely on advanced machinery to meet consumer expectations for quality, safety, and sustainability. With a growing emphasis on automation, energy efficiency, and the demand for specialized dairy products, the market for dairy processing equipment is poised to expand steadily over the coming years.

More Trending Latest Reports By Polaris Market Research:

Specialty Super Absorbent Polymer Market

Sustainable Manufacturing Market