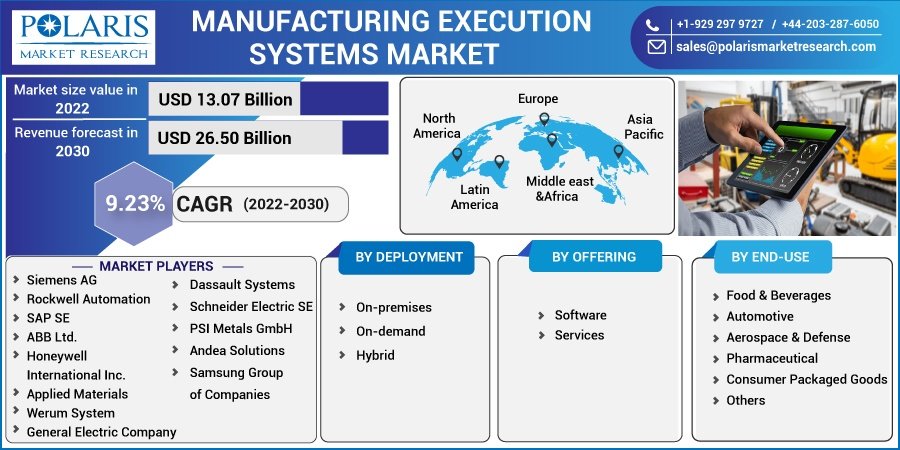

The Manufacturing Execution Systems (MES) market is set to experience substantial growth, reaching a market size of USD 26.50 billion by 2030, with a robust CAGR of 9.23% during the forecast period from 2022 to 2030.

This growth is driven by the increasing need for real-time monitoring, improved efficiency, enhanced productivity, and reduced operational costs in manufacturing processes. As businesses strive to meet customer demand, maintain high levels of product quality, and optimize manufacturing operations, MES solutions have become an integral part of modern manufacturing strategies.

Market Overview

Manufacturing Execution Systems (MES) are software-based solutions that help manufacturers manage and control their production processes on the shop floor. MES bridges the gap between enterprise-level systems, such as Enterprise Resource Planning (ERP), and production-level systems, providing real-time data and insights into manufacturing operations. MES systems enable businesses to monitor inventory, track production progress, ensure product quality, and reduce downtime by providing a centralized platform for data-driven decision-making.

By offering real-time visibility into operations, MES solutions enable manufacturers to track production performance, manage resources efficiently, reduce waste, and maintain regulatory compliance. As the manufacturing industry increasingly embraces automation and digitization, the demand for MES solutions is expected to rise significantly.

𝐄𝐱𝐩𝐥𝐨𝐫𝐞 𝐓𝐡𝐞 𝐂𝐨𝐦𝐩𝐥𝐞𝐭𝐞 𝐂𝐨𝐦𝐩𝐫𝐞𝐡𝐞𝐧𝐬𝐢𝐯𝐞 𝐑𝐞𝐩𝐨𝐫𝐭 𝐇𝐞𝐫𝐞:

https://www.polarismarketresearch.com/industry-analysis/manufacturing-execution-systems-market

Market Drivers

- Increasing Demand for Operational Efficiency

- As manufacturing industries face increasing pressure to reduce costs and improve operational efficiency, MES solutions have become essential for streamlining production processes. MES systems help optimize the production workflow, minimize delays, and reduce downtime, resulting in improved productivity and cost savings. Manufacturers are adopting MES to ensure that resources are utilized effectively, which ultimately leads to higher profitability.

- Rise of Smart Manufacturing and Industry 4.0

- Industry 4.0, or the fourth industrial revolution, emphasizes the integration of advanced technologies such as IoT (Internet of Things), AI (Artificial Intelligence), big data analytics, and automation to create “smart factories.” MES plays a critical role in the success of Industry 4.0 initiatives by enabling real-time monitoring and control of production processes. As manufacturers adopt IoT devices and smart sensors, the demand for MES solutions to manage and analyze the data generated by these systems is increasing.

- Growing Need for Real-Time Data and Visibility

- The ability to access real-time data on production performance, equipment status, and inventory levels is crucial for making informed decisions. MES systems provide manufacturers with real-time insights into their operations, allowing them to identify bottlenecks, optimize workflows, and improve product quality. This level of visibility is becoming increasingly important as manufacturers seek to improve their agility and responsiveness to market demands.

- Increased Focus on Quality Management

- Ensuring high-quality products is a top priority for manufacturers, especially in industries such as automotive, pharmaceuticals, and electronics. MES solutions enable manufacturers to implement robust quality control processes by monitoring production variables in real time. MES systems help track product defects, ensure compliance with regulatory standards, and enable manufacturers to make immediate corrections, ensuring consistent product quality.

- Growing Adoption of Cloud-Based MES Solutions

- The transition to cloud-based MES solutions is accelerating, as businesses seek to lower upfront capital expenses and reduce the complexity of on-premises systems. Cloud-based MES solutions offer flexibility, scalability, and the ability to access production data remotely. Manufacturers can also benefit from automatic software updates, reduced IT maintenance costs, and improved collaboration between different stakeholders in the production process.

Challenges in the MES Market

- High Implementation Costs

- Implementing MES systems can be a significant investment for manufacturers, particularly for small and medium-sized enterprises (SMEs). The costs associated with purchasing, customizing, and integrating MES solutions with existing systems can be a barrier to adoption. Additionally, the implementation process often requires extensive training for employees, which can add to the overall cost.

- Complexity of Integration with Existing Systems

- Integrating MES with existing enterprise systems, such as ERP, Supply Chain Management (SCM), and Product Lifecycle Management (PLM), can be complex. Manufacturers often struggle with data silos, incompatible software systems, and legacy infrastructure. Effective integration is essential for ensuring seamless data flow across the organization, which can sometimes be challenging and time-consuming.

- Data Security and Privacy Concerns

- With the increasing amount of data generated by MES solutions, manufacturers must prioritize cybersecurity to protect sensitive information. Data breaches, cyber-attacks, and unauthorized access to production data can have severe consequences for manufacturers, leading to operational disruptions, financial losses, and reputational damage. As MES systems increasingly rely on cloud-based platforms, ensuring robust data security protocols is becoming a critical concern.

Market Segmentation

The MES market can be segmented based on type, deployment model, industry, and region.

By Type

- On-Premises MES Solutions

- On-premises MES solutions are installed and hosted on a company’s internal servers and infrastructure. These solutions offer manufacturers more control over their data and systems but can come with higher upfront costs and ongoing maintenance expenses.

- Cloud-Based MES Solutions

- Cloud-based MES solutions are hosted on the cloud and offer businesses greater scalability, flexibility, and accessibility. These solutions reduce the need for heavy IT infrastructure and allow manufacturers to manage production data remotely. The growing adoption of cloud computing is expected to drive the demand for cloud-based MES solutions.

By Deployment Model

- Single-Site MES

- Single-site MES solutions are designed for manufacturers with a single production facility. These solutions are focused on managing production processes and improving efficiency at a single location.

- Multi-Site MES

- Multi-site MES solutions are designed for manufacturers with multiple production facilities or a global presence. These solutions enable businesses to manage and monitor production across different locations, ensuring consistency in production processes and performance.

By Industry

- Automotive

- The automotive industry is a major adopter of MES solutions, as manufacturers in this sector require highly efficient and flexible production processes. MES helps optimize assembly lines, manage inventory, and ensure compliance with regulatory standards.

- Pharmaceuticals

- In the pharmaceutical industry, MES systems are used to track and manage the production of drugs, ensuring compliance with industry regulations such as Good Manufacturing Practices (GMP). MES solutions help improve product quality and reduce the risk of errors in production.

- Electronics and Semiconductor

- The electronics and semiconductor industries rely heavily on MES solutions to manage complex production processes and high product complexity. MES systems help streamline manufacturing workflows, track product performance, and ensure high-quality output.

- Food and Beverages

- MES solutions are increasingly being adopted in the food and beverage industry to manage production efficiency, track ingredients, and ensure compliance with food safety regulations. MES systems help manufacturers optimize production schedules and improve quality control.

- Consumer Goods

- Manufacturers of consumer goods use MES solutions to manage large-scale production processes, optimize supply chains, and maintain product quality. MES systems enable companies to track the production of various consumer goods, ensuring consistency and reducing production costs.

By Region

- North America

- North America is the largest market for MES solutions, driven by the presence of major manufacturers and the early adoption of Industry 4.0 technologies. The demand for MES solutions is high in industries such as automotive, pharmaceuticals, and electronics.

- Europe

- Europe is a significant market for MES, with countries like Germany, the UK, and France leading the adoption of manufacturing technologies. The region’s emphasis on advanced manufacturing, automation, and digital transformation is fueling the growth of MES solutions.

- Asia-Pacific

- The Asia-Pacific region is expected to witness significant growth in the MES market, driven by the rapid industrialization and adoption of digital technologies in countries like China, India, and Japan. The growing manufacturing sector and increasing demand for automation are contributing to the region’s growth.

- Latin America

- Latin America is experiencing increasing adoption of MES solutions, particularly in industries such as automotive, food and beverage, and consumer goods. The region’s growing manufacturing sector is driving the demand for advanced production management systems.

- Middle East & Africa

- The Middle East and Africa are emerging markets for MES solutions, with manufacturers in sectors such as oil and gas, chemicals, and construction adopting these solutions to improve efficiency and productivity.

Competitive Landscape

The Manufacturing Execution Systems (MES) market is competitive, with several key players offering a range of MES solutions. Some of the major players in the market include:

- Siemens AG

- Rockwell Automation

- SAP SE

- ABB Ltd.

- Honeywell International Inc.

- Applied Materials

- Werum System

- General Electric Company

- Emerson Electric

- Epicore Software Corporation

- Oracle Group

- Dassault Systems

- Schneider Electric SE

- PSI Metals GmbH

- Andea Solutions

- and Samsung Group of Companies.

These companies are focusing on product innovation, strategic partnerships, and acquisitions to expand their market share and strengthen their presence in the MES market.

Conclusion

The Manufacturing Execution Systems (MES) market is poised for strong growth as manufacturers worldwide seek to enhance efficiency, improve product quality, and optimize production processes. The adoption of Industry 4.0 technologies, the increasing demand for real-time data, and the need for seamless integration with enterprise systems are key factors driving the demand for MES solutions.

𝐁𝐫𝐨𝐰𝐬𝐞 𝐌𝐨𝐫𝐞 𝐑𝐞𝐬𝐞𝐚𝐫𝐜𝐡 𝐑𝐞𝐩𝐨𝐫𝐭𝐬:

Software-Defined Data Center Market

Cloud Services Brokerage Market

Identity Security Posture Management (ISPM) Market

Education Technology SaaS Tools Market

Indonesia, Philippines, Malaysia, and Cambodia Debt Collection Software Market