The South East Asia polyurethane adhesives market is experiencing substantial growth due to the increasing demand for high-performance adhesives across various industries. Polyurethane adhesives, known for their excellent bonding strength, durability, and versatility, are extensively used in industries such as automotive, construction, packaging, textiles, and electronics.

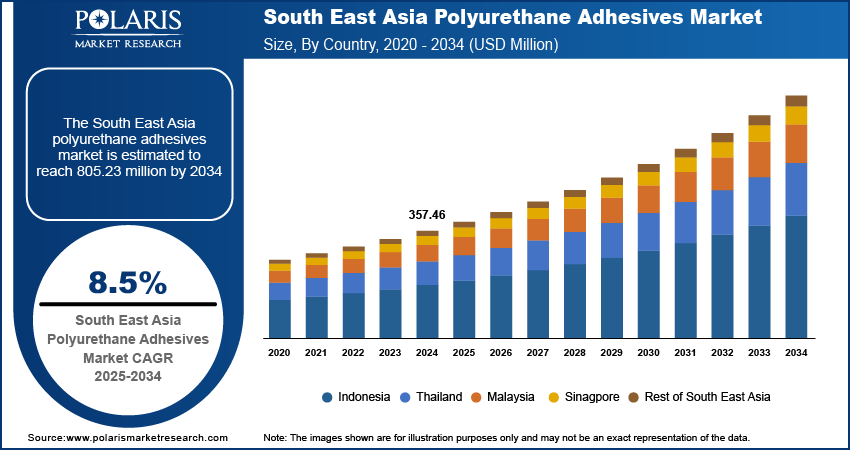

The South East Asia polyurethane adhesives market size was valued at USD 357.46 million in 2024. The market is projected to grow from USD 387.06 million in 2025 to USD 805.23 million by 2034, exhibiting a CAGR of 8.5% during 2025–2034.

This article examines the market overview, key market growth drivers, market challenges, regional analysis, and leading companies that are contributing to the development of the polyurethane adhesives market in Southeast Asia.

Market Overview

Polyurethane adhesives are a type of polymer that offers excellent adhesion, flexibility, and resistance to chemicals, temperature variations, and moisture. These adhesives are widely used in bonding materials such as metals, plastics, glass, and wood, making them ideal for a range of applications, from automotive manufacturing to construction and consumer goods packaging.

The South East Asia polyurethane adhesives market is driven by rapid industrialization, growing demand from end-user industries, and the increasing preference for eco-friendly and high-performance adhesives. With advancements in polyurethane technology, these adhesives are now available in various forms, including one-component and two-component systems, which can be customized to meet specific application needs. Their use in construction, automotive, and packaging industries is particularly notable, as these sectors are experiencing significant growth in the region.

Key Market Growth Drivers

Several factors are contributing to the growth of the polyurethane adhesives market in Southeast Asia:

-

Growing Demand from the Automotive Industry

Southeast Asia has become a global hub for automotive manufacturing, with significant production bases in countries like Thailand, Indonesia, and Malaysia. The automotive sector in the region is witnessing robust growth, driven by increasing vehicle production, higher consumer demand, and the rise of electric vehicles (EVs). Polyurethane adhesives are extensively used in automotive applications for bonding components, such as windows, doors, and interior panels, thanks to their superior performance in high-stress environments. The automotive industry’s expansion is expected to fuel demand for polyurethane adhesives in Southeast Asia.

-

Surging Demand from the Construction Sector

The construction sector in Southeast Asia is one of the fastest-growing industries, with rapid urbanization and infrastructure development projects underway across countries like Vietnam, Thailand, and Indonesia. Polyurethane adhesives are increasingly being used in construction for applications such as flooring, insulation, and waterproofing. Their ability to provide durable, flexible, and weather-resistant bonds makes them ideal for use in building materials, particularly in the growing demand for high-performance, energy-efficient construction materials.

-

Packaging Industry Growth

The packaging industry in Southeast Asia is growing rapidly due to increasing demand from the food and beverage, pharmaceuticals, and consumer goods sectors. Polyurethane adhesives are commonly used in flexible packaging, labels, and laminates because they offer excellent adhesion and durability. As the demand for advanced packaging solutions rises, especially in terms of sustainability and performance, the use of polyurethane adhesives in packaging applications is expected to increase in Southeast Asia.

-

Rising Preference for Eco-Friendly Products

With increasing environmental awareness, there is a growing preference for eco-friendly products in Southeast Asia. Consumers and businesses are seeking adhesives that offer both high performance and low environmental impact. Polyurethane adhesives have evolved to meet these demands, with manufacturers developing low-VOC (volatile organic compounds) formulations that are both safe and sustainable. This trend toward environmentally friendly adhesives is driving the growth of the polyurethane adhesives market in the region.

Browse Full Insights:

Market Challenges

Despite the promising growth prospects, there are several challenges hindering the growth of the polyurethane adhesives market in Southeast Asia:

-

High Cost of Raw Materials

Polyurethane adhesives are typically more expensive than other types of adhesives due to the cost of raw materials, such as isocyanates and polyols, which are key components in their production. The price volatility of these raw materials can impact the overall cost of production and, in turn, the pricing of polyurethane adhesives. This poses a challenge, especially in price-sensitive markets, where manufacturers may opt for lower-cost alternatives.

-

Technological Complexity in Production

The production of high-quality polyurethane adhesives requires advanced manufacturing processes and technologies. As the demand for customized, high-performance adhesives increases, manufacturers need to invest in research and development (R&D) to develop new formulations that meet specific industry requirements. The technological complexity involved in the production process can be a barrier to entry for new market players and add additional costs to established manufacturers.

-

Strict Regulatory Standards

The polyurethane adhesives market is subject to stringent regulations, particularly concerning the use of hazardous chemicals and VOC emissions. In Southeast Asia, regulatory bodies are increasingly enforcing stricter environmental standards, which may increase compliance costs for manufacturers. Additionally, meeting the regulatory requirements for safety and performance testing can be a time-consuming and costly process.

-

Competition from Alternative Adhesives

Polyurethane adhesives face competition from other types of adhesives, such as epoxy and acrylic adhesives, which are also used in industries like automotive, construction, and packaging. While polyurethane adhesives offer unique benefits, other adhesives may offer lower costs or superior properties for specific applications. Manufacturers must continue to innovate and improve the performance of polyurethane adhesives to maintain their competitive edge.

Market Segmentation

The South East Asia polyurethane adhesives market can be segmented based on product type, application, and region.

By Product Type

-

One-Component Polyurethane Adhesives These adhesives are ready to use and do not require mixing with hardeners or other components. They offer ease of use, long shelf life, and excellent bonding properties, making them ideal for automotive, construction, and packaging applications.

-

Two-Component Polyurethane Adhesives These adhesives require mixing before use and provide superior strength and durability. They are widely used in industries that demand high-performance adhesives, such as automotive and construction.

By Application

-

Automotive Polyurethane adhesives are extensively used in the automotive industry for bonding metal, glass, plastic, and composite materials. They are particularly popular for window bonding, structural bonding, and sealing applications.

-

Construction In the construction industry, polyurethane adhesives are used in a variety of applications, including flooring, insulation, and bonding materials such as wood, concrete, and metal. Their durability and resistance to environmental factors make them ideal for both residential and commercial construction.

-

Packaging Polyurethane adhesives are commonly used in flexible and rigid packaging applications, providing excellent adhesion and moisture resistance. They are particularly used in food and beverage packaging due to their non-toxic and safe bonding properties.

-

Others Other applications include the electronics industry, where polyurethane adhesives are used for bonding components in products like smartphones and televisions, as well as in the textiles industry for bonding fabrics.

Regional Analysis

1. Thailand

Thailand is one of the largest markets for polyurethane adhesives in Southeast Asia, driven by the country’s growing automotive and construction sectors. Thailand’s well-established automotive manufacturing base and the ongoing infrastructure development projects make it a significant contributor to the market. Additionally, the packaging industry in Thailand is expanding, further driving demand for polyurethane adhesives.

2. Indonesia

Indonesia’s rapidly growing economy and industrialization are key factors driving the polyurethane adhesives market. The automotive and construction sectors in the country are expanding, and the demand for advanced adhesives is increasing. As Indonesia’s manufacturing capabilities continue to improve, the demand for high-performance adhesives is expected to rise.

3. Malaysia

Malaysia’s automotive industry is one of the most advanced in Southeast Asia, making it a major market for polyurethane adhesives. The country’s commitment to sustainability and environmental standards is also encouraging the adoption of eco-friendly adhesive solutions, which bodes well for the market’s growth. The construction sector is also experiencing growth, driven by urbanization and infrastructure development.

4. Vietnam

Vietnam is witnessing a surge in industrialization and urbanization, which is driving demand for high-performance adhesives. The construction and packaging industries are particularly strong in Vietnam, leading to increased demand for polyurethane adhesives. Additionally, Vietnam’s growing automotive industry is expected to boost market growth further.

5. Philippines

In the Philippines, the construction and automotive sectors are expanding, driving the demand for polyurethane adhesives. The country’s growing middle class and increasing disposable income are further fueling demand for packaged goods, which, in turn, increases the need for adhesives in packaging.

Conclusion

The South East Asia polyurethane adhesives market is poised for significant growth, driven by the increasing demand from the automotive, construction, and packaging industries. Technological advancements, the shift toward sustainable solutions, and the growing need for high-performance adhesives are key factors contributing to market expansion. While challenges such as raw material costs and regulatory compliance exist, the market’s long-term outlook remains positive, with significant opportunities for growth in key Southeast Asian economies such as Thailand, Indonesia, and Vietnam.

More Trending Latest Reports By Polaris Market Research:

Infrastructure Asset Management Market