The rubber molding market is witnessing steady growth, driven by the increasing demand for rubber molded products across various industries such as automotive, healthcare, industrial, and consumer goods.

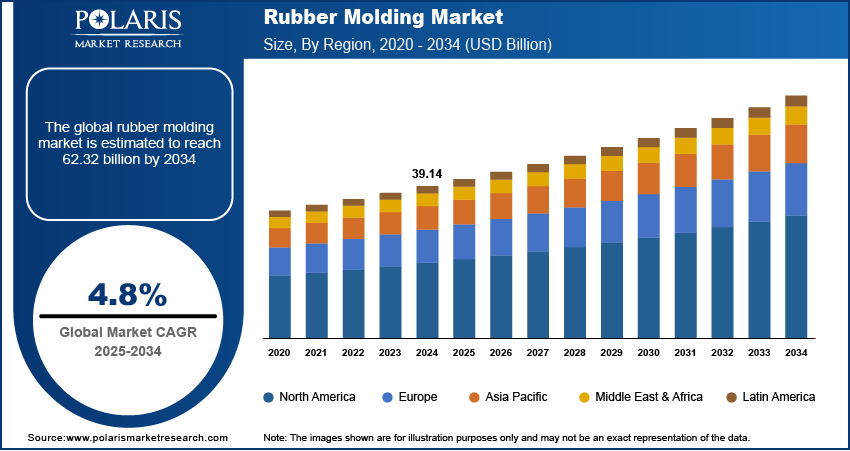

The global rubber molding market size was valued at USD 39.14 billion in 2024. The market is projected to grow from USD 40.94 billion in 2025 to USD 62.32 billion by 2034, at a CAGR of 4.8% from 2025 to 2034.

Rubber molding, which involves shaping rubber compounds into specific forms using heat and pressure, offers advantages such as durability, flexibility, and cost-effectiveness. As industries demand products with superior performance, greater efficiency, and sustainability, rubber molding continues to evolve, making it a crucial part of modern manufacturing processes. This press release delves into the rubber molding market, exploring key growth drivers, challenges, regional analysis, and the leading companies making significant strides in this space.

Market Overview: Growth and Evolution of Rubber Molding Techniques

Rubber molding is a process that involves shaping and forming rubber into products through various molding techniques such as injection molding, compression molding, transfer molding, and blow molding. These methods are used to produce a wide range of products, including seals, gaskets, automotive parts, medical devices, and consumer goods. The process allows for high precision and cost-efficiency, making it essential for industries requiring high-performance rubber components.

The versatility of rubber in molding applications is one of its key advantages. Rubber molded products are widely used in automotive components like gaskets, seals, and bushings due to their durability and resistance to wear and chemicals. In healthcare, rubber molding plays a critical role in the production of medical devices such as catheters, syringe seals, and surgical gloves, offering biocompatibility and flexibility. The industrial sector also relies on rubber molded components in machinery, seals, and hoses for their resistance to heat, pressure, and friction.

With technological advancements, manufacturers are now able to produce rubber molded products in larger volumes with greater consistency and lower waste, thus driving the market’s expansion. Additionally, eco-friendly rubber molding solutions are gaining popularity due to rising environmental awareness, pushing the industry toward sustainable practices and materials.

Key Market Growth Drivers

Several factors are fueling the growth of the rubber molding market, ranging from technological advancements to industry-specific demand. Some of the most significant growth drivers include:

1. Rising Demand from the Automotive Industry

The automotive sector is one of the largest consumers of rubber molded products, such as seals, gaskets, bushings, and vibration dampers. As automotive manufacturers strive to enhance the performance, safety, and comfort of vehicles, rubber components play a critical role in achieving these goals. With the increasing production of electric vehicles (EVs) and hybrid vehicles, there is a growing need for high-quality rubber components that can withstand the unique demands of these vehicles.

In addition to the growing demand for automotive parts, the shift toward more sustainable vehicles is also driving the need for eco-friendly and recyclable rubber materials. Rubber molding allows for the production of lightweight and durable components, which are essential for improving vehicle efficiency and performance.

2. Advancements in Molding Technologies

Technological advancements in rubber molding techniques, such as injection molding and compression molding, are revolutionizing the production of rubber parts. These techniques allow manufacturers to produce rubber components with high precision and minimal waste, improving efficiency and reducing production costs. Injection molding is particularly popular because it allows for the creation of complex, high-quality rubber parts with faster cycle times.

In addition, the integration of automation and robotics into the rubber molding process is further improving production efficiency and consistency, enabling manufacturers to meet the growing demand for high-volume production.

3. Growing Healthcare Applications

The healthcare sector continues to be a major contributor to the rubber molding market. Rubber molded products, such as surgical gloves, seals, and medical tubing, are essential in maintaining the safety, quality, and reliability of medical devices. The demand for healthcare products is growing due to the increasing global population, aging demographics, and rising healthcare standards.

Medical rubber molding solutions offer biocompatibility and flexibility, making them ideal for use in a wide range of medical devices. Furthermore, with the global shift toward more personalized and minimally invasive medical treatments, rubber molded products will continue to play a significant role in medical device manufacturing.

4. Sustainability and Eco-Friendly Molding Solutions

As environmental concerns continue to rise, the demand for sustainable and eco-friendly products is increasing across industries. In response to this demand, rubber molding manufacturers are exploring ways to integrate recyclable materials and more environmentally friendly molding techniques into their production processes. Recycled rubber, bio-based rubbers, and green molding technologies are gaining traction as industries strive to reduce their environmental footprint.

Rubber molding’s ability to produce durable, long-lasting products means that the need for replacements is lower, contributing to overall sustainability. Manufacturers are also focusing on minimizing waste during the molding process, further enhancing the eco-friendliness of rubber molding.

Browse Full Insights:

https://www.polarismarketresearch.com/industry-analysis/rubber-molding-market

Market Challenges

While the rubber molding market is growing steadily, several challenges may hinder its expansion in the coming years. These challenges include:

1. Rising Raw Material Costs

One of the most significant challenges faced by rubber molding manufacturers is the rising cost of raw materials. Rubber is primarily derived from petroleum-based sources, and fluctuations in the price of crude oil directly affect the cost of raw rubber. Additionally, the prices of other materials used in the molding process, such as additives and fillers, can also increase, impacting the overall cost structure of the market.

Manufacturers are exploring alternative materials and sustainable sourcing options to mitigate these cost increases. However, finding cost-effective and reliable alternatives remains a challenge.

2. Environmental and Regulatory Compliance

Environmental regulations related to the use of rubber and other materials in the manufacturing process are becoming stricter. Regulations surrounding waste disposal, emissions, and the use of hazardous chemicals are being enforced in many regions, which increases the complexity of rubber molding operations. Manufacturers must ensure compliance with these regulations while maintaining the efficiency and quality of their production processes.

Moreover, there is increasing pressure from consumers and regulatory bodies to shift toward more sustainable practices, which may require significant investment in new technologies and materials.

3. Technological Limitations in Molding Complex Designs

While rubber molding techniques have advanced, producing highly complex and intricate designs still presents a challenge. Some molding methods, particularly compression molding, may face limitations when it comes to producing parts with intricate geometries and fine details. This requires manufacturers to invest in more advanced technologies and equipment to overcome such limitations.

Additionally, while injection molding offers high precision, it requires careful control of the molding process to avoid defects such as air pockets, inconsistent thickness, or improper curing.

Regional Analysis: Global Growth Trends in Rubber Molding

The rubber molding market is growing globally, driven by demand from key industries such as automotive, healthcare, and industrial manufacturing. The market’s growth is regionally diverse, with strong performance in North America, Europe, Asia-Pacific, and emerging markets.

North America

North America, particularly the United States, is a major player in the rubber molding market, owing to the region’s advanced automotive and healthcare industries. The demand for rubber molded components in the automotive and medical device sectors is expected to continue to rise, driving the market’s growth. Additionally, the increasing adoption of advanced molding technologies is helping North American manufacturers improve production efficiency and reduce waste.

Europe

Europe holds a significant share of the rubber molding market, driven by strong industrial manufacturing and automotive sectors in countries like Germany, France, and Italy. Europe is also seeing increasing demand for eco-friendly and sustainable rubber molding solutions. The growing focus on reducing automotive emissions and improving vehicle performance is further driving the demand for advanced rubber components in the region.

Asia-Pacific

The Asia-Pacific (APAC) region is expected to experience the highest growth in the rubber molding market. Countries such as China, India, Japan, and South Korea are major contributors to this growth, thanks to their expanding automotive and industrial sectors. Additionally, the rising demand for healthcare products in the region, particularly in countries with aging populations like Japan, is driving the adoption of rubber molding technologies.

Latin America

In Latin America, the rubber molding market is expanding steadily, particularly in Brazil and Mexico, where the automotive and manufacturing sectors are growing rapidly. The need for high-quality rubber components in the automotive and industrial sectors is supporting market growth in this region.

Middle East and Africa

The Middle East and Africa (MEA) region is witnessing moderate growth in the rubber molding market, driven by increased industrial activity and the demand for automotive parts in countries like the UAE and Saudi Arabia. The region’s growing focus on infrastructure development and energy sectors is also contributing to the demand for rubber molded components.

Key Companies in the Rubber Molding Market

Several companies are leading the way in the rubber molding market, including:

-

Freudenberg Group

-

Cooper-Standard Automotive

-

Trelleborg AB

-

Parker Hannifin Corporation

-

U.S. Rubber Company

-

Hutchinson

-

Elastomer Engineering

These companies are focusing on expanding their product portfolios, adopting sustainable practices, and incorporating advanced technologies into their production processes to maintain a competitive edge in the rubber molding market.

Conclusion

The rubber molding market is poised for continued growth as the demand for high-performance, cost-effective, and sustainable rubber components increases across various industries. Key growth drivers, such as the rising demand from the automotive sector, advancements in molding technologies, and the growing healthcare applications, are contributing to the expansion of the market. However, challenges such as rising raw material costs and the need for environmental compliance must be addressed for the market to reach its full potential. With a diverse regional landscape and ongoing technological innovations, the rubber molding market offers significant opportunities for manufacturers to capitalize on emerging trends and increase market share.

More Trending Latest Reports By Polaris Market Research:

Testing, Inspection, and Certification Market

Surgical Planning Software Market

Penetration Testing as a Service Market