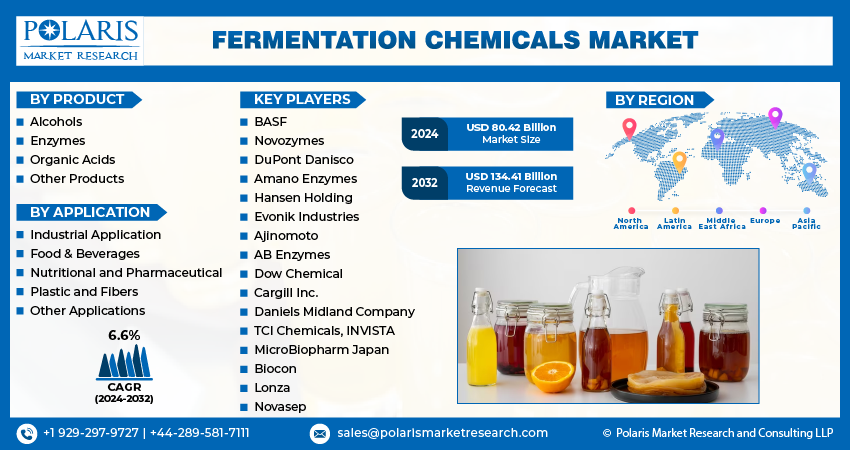

According to the research report, the global fermentation chemicals market was valued at USD 75.49 billion in 2023 and is expected to reach USD 134.41 billion by 2032, to grow at a CAGR of 6.6% during the forecast period.

The Fermentation Chemicals Market is witnessing substantial growth across diverse end-use industries such as food and beverages, pharmaceuticals, agriculture, and bio-based chemicals. As global industries transition toward environmentally sustainable manufacturing processes, fermentation chemicals are gaining prominence for their ability to replace synthetic and petroleum-derived alternatives. Derived through microbial processes, these chemicals offer benefits such as reduced toxicity, lower greenhouse gas emissions, and the ability to utilize renewable feedstocks, thereby aligning with global sustainability goals.

Fermentation chemicals serve as essential catalysts in microbial fermentation processes that produce a wide array of products, including alcohols, enzymes, amino acids, organic acids, and vitamins. As innovations in industrial biotechnology evolve and as demand for natural ingredients accelerates, the fermentation chemicals market is positioned to expand significantly in the years to come.

Market Overview

The global fermentation chemicals market is segmented by product type (alcohols, enzymes, organic acids), application (industrial, food & beverage, pharmaceutical & personal care, plastics & fibers, animal feed), and feedstock (corn, sugar beet, molasses, and others). Alcohols, particularly ethanol and butanol, dominate the market, followed by enzymes used in detergents, food processing, and bio-refineries. Organic acids such as citric acid, lactic acid, and acetic acid have gained traction due to their increasing use in biodegradable plastics, nutraceuticals, and food preservatives.

Market expansion is driven by shifting consumer preferences toward natural and organic products, as well as stringent regulations promoting bio-based and eco-friendly industrial processes. The proliferation of biorefineries, integration of synthetic biology, and government support for green chemistry are shaping a favorable landscape for fermentation chemicals globally.

Key Market Growth Drivers

-

Surging Demand for Bio-Based and Eco-Friendly Products

The push for sustainable development and circular economy models has elevated the demand for bio-based products across industries. Fermentation chemicals, produced from renewable biomass, are replacing petrochemical counterparts in products ranging from bioplastics to detergents. The growing awareness among consumers and manufacturers about the environmental impact of traditional chemicals has significantly contributed to the rise in fermentation-based alternatives. -

Growth in the Food and Beverage Industry

Fermentation chemicals play a vital role in the food and beverage industry, where they are used in the production of dairy, alcoholic beverages, nutritional supplements, and flavor enhancers. Enzymes help break down complex carbohydrates and proteins, improving food texture and shelf life, while organic acids serve as preservatives and pH regulators. As demand for processed and functional foods increases, so too does the demand for safe and natural fermentation-derived ingredients. -

Expansion of the Pharmaceutical and Healthcare Sectors

The pharmaceutical industry is a key driver of the fermentation chemicals market, utilizing these compounds to produce antibiotics, amino acids, vitamins, and therapeutic proteins. The rising prevalence of chronic diseases, aging populations, and increasing investment in biologics and vaccines are boosting the demand for fermentation technologies. Lactic acid, citric acid, and fermentation-derived enzymes are widely used in formulations, drug delivery, and pharmaceutical excipients. -

Technological Advancements in Fermentation and Synthetic Biology

Breakthroughs in genetic engineering, metabolic pathway design, and microbial strain optimization are enhancing the efficiency and yield of fermentation processes. Synthetic biology tools are enabling the development of tailor-made organisms capable of producing high-value chemicals, reducing production time, and minimizing waste. Continuous fermentation systems and downstream processing technologies are also driving cost reductions and scaling capabilities for commercial production.

Browse Full Insights:

https://www.polarismarketresearch.com/industry-analysis/fermentation-chemicals-market

Market Challenges

Despite robust growth prospects, the fermentation chemicals market faces several hurdles that must be addressed to achieve its full potential.

-

High Production and Operational Costs

Although fermentation processes are environmentally beneficial, they often incur high production costs due to the need for controlled environments, sterilization, and downstream purification. The cost of feedstocks and bioreactors, along with energy consumption during fermentation, can hinder widespread commercial adoption—especially when compared to cost-efficient petrochemical routes. Efforts to improve process efficiency and develop low-cost substrates are critical to overcoming this barrier. -

Feedstock Availability and Competition

The supply of renewable feedstocks such as corn, sugarcane, and molasses is subject to seasonal variations and geopolitical factors. These raw materials are also in demand across other industries like biofuels, food production, and animal feed, creating intense competition. Diversifying the feedstock base by utilizing agricultural residues, algae, and industrial waste can alleviate supply pressure and improve sustainability. -

Complex and Lengthy Regulatory Approvals

Fermentation chemicals used in food, pharmaceuticals, and personal care products must comply with strict regulatory standards to ensure safety and efficacy. Navigating these regulatory frameworks can be time-consuming and expensive, delaying product launch and commercialization. Global harmonization of regulations and streamlined approval pathways are necessary to reduce entry barriers for new fermentation-derived products. -

Technical Limitations in Scale-Up

While fermentation processes are effective at lab or pilot scale, scaling them up to industrial levels presents technical challenges. Issues such as contamination, process control, and product consistency can arise during scale-up. Investment in advanced bioprocess monitoring, automation, and process analytical technologies (PAT) is essential to ensure consistent and cost-effective large-scale production.

Regional Analysis

-

North America

North America holds a significant share in the global fermentation chemicals market, supported by advanced biotechnology infrastructure, strong research and development activity, and demand for sustainable industrial processes. The U.S. leads the market with its large-scale bio-refineries, food and beverage companies, and pharmaceutical manufacturers. Federal initiatives promoting bio-based industries and clean energy are expected to further stimulate market growth in the region. -

Europe

Europe is another key region, driven by stringent environmental regulations and the European Union’s support for green and circular economies. Countries like Germany, France, and the Netherlands are heavily investing in bio-innovation, and fermentation technologies are central to their industrial biotechnology strategies. The market also benefits from consumer demand for organic food, natural cosmetics, and eco-friendly cleaning agents. -

Asia Pacific

Asia Pacific is the fastest-growing region in the fermentation chemicals market, with rapid industrialization, urbanization, and a rising middle class fueling demand for packaged food, personal care, and pharmaceuticals. China and India are major players due to their vast agricultural base, growing biotechnology sectors, and increasing adoption of green manufacturing practices. Government support for bioeconomy development and investment in infrastructure are key growth drivers in the region. -

Latin America

Latin America is gradually expanding its footprint in the fermentation chemicals market. Brazil, in particular, has a robust sugarcane-based ethanol industry and is leveraging its biomass resources for fermentation-based production. The region’s growing food processing industry and awareness about sustainable agriculture present opportunities for further market development. -

Middle East and Africa

Although still at a nascent stage, the Middle East and Africa region is beginning to adopt fermentation chemicals in agriculture, food processing, and water treatment. The push for food security, self-sufficiency, and industrial diversification is likely to spur investments in bioprocessing technologies. Regional governments are recognizing the potential of fermentation in driving sustainable economic growth.

Key Companies in the Fermentation Chemicals Market

The fermentation chemicals market is competitive and marked by a mix of multinational manufacturers and specialized biotechnology firms. Companies are focusing on capacity expansion, strategic partnerships, and investments in R&D to strengthen their market position. Innovations in microbial engineering, fermentation pathway optimization, and bio-refining are shaping the next generation of fermentation chemicals.

Key market players are integrating vertically, securing feedstock supply, and exploring new end-use applications to diversify their product portfolios. Collaborations with academic institutions and government agencies are also fueling innovation and accelerating commercialization timelines.

Conclusion

The global fermentation chemicals market is poised for dynamic growth, supported by strong demand across key sectors, increasing environmental regulations, and technological innovation. As industries transition away from petroleum-based chemicals, fermentation-based production offers a sustainable, efficient, and eco-friendly alternative.

While challenges such as feedstock competition, high costs, and scale-up limitations persist, continuous innovation and supportive policy frameworks are enabling the market to overcome these hurdles. Regions like North America, Europe, and Asia Pacific are expected to lead the charge, while emerging markets present untapped opportunities.

More Trending Latest Reports By Polaris Market Research:

Major Innovations in the Electric Scooter to Positively Influence the Global Industry