The global pharmaceutical processing seals market is entering a phase of rapid expansion, driven by the growing demand for contamination-free manufacturing environments and advanced pharmaceutical formulations. From maintaining integrity during production to ensuring strict compliance with international health and safety regulations, pharmaceutical processing seals play a pivotal role across all segments of the drug manufacturing process.

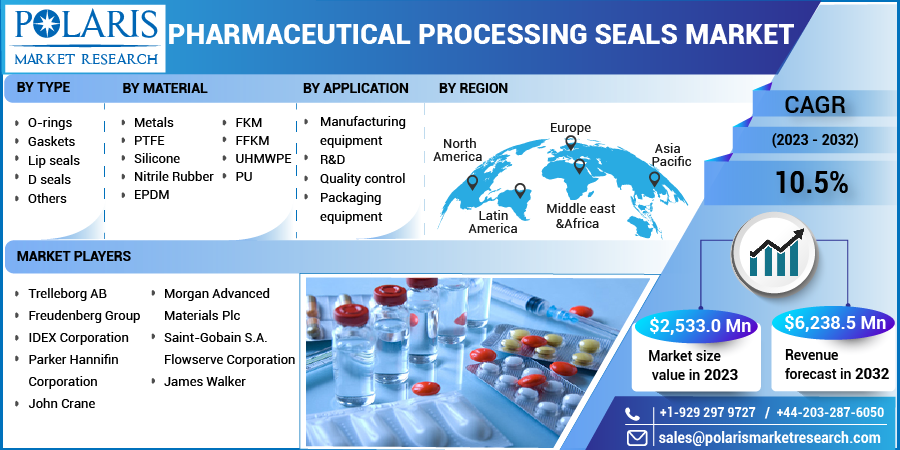

The global pharmaceutical processing seals market size is expected to reach USD 6,238.5 million by 2032, according to a new study by Polaris Market Research.

Market Overview

Pharmaceutical processing seals are essential components used in manufacturing equipment to prevent leaks, block contamination, and maintain sterile production environments. These seals are engineered from high-grade materials like PTFE, EPDM, silicone, and Viton to withstand extreme chemical, temperature, and pressure conditions.

With rising complexity in drug formulations, especially in biopharmaceutical production, the industry requires seals that are both durable and chemically inert. These characteristics are especially vital in environments where cross-contamination, leakage, or non-compliance can lead to product recalls or serious health risks.

The integration of automation and digitization in pharmaceutical plants has also led to higher standards for precision-engineered sealing systems, accelerating demand for advanced pharmaceutical equipment seals.

Key Market Growth Drivers

1. Increasing Demand for Sterile and Contamination-Free Manufacturing

One of the primary growth drivers is the heightened need for sterile manufacturing conditions. With regulatory bodies such as the FDA, EMA, and WHO mandating stringent cleanliness and safety protocols, pharmaceutical companies are investing heavily in sealing technologies that meet cleanroom and aseptic standards.

Pharmaceutical seals help prevent product contamination during the formulation, packaging, and filling processes—critical in both traditional small-molecule drugs and modern biological therapies. The growing prevalence of infectious diseases, including recent pandemics, has further underscored the importance of robust seal technologies.

2. Expansion of the Biopharmaceutical Sector

The surging growth of the global biopharmaceutical production sector has created new opportunities in the pharmaceutical sealing market. Biologics, including monoclonal antibodies, cell therapies, and vaccines, are highly sensitive to contamination and environmental changes. Processing these substances requires ultra-hygienic equipment, where chemical-resistant and sterile seals are non-negotiable.

As biologics continue to make up a larger share of the pharmaceutical pipeline, demand for high-performance sealing components is expected to increase significantly.

3. Technological Advancements in Seal Materials and Designs

Recent innovations in seal material technology, such as the development of chemical-resistant seals, have improved the durability, safety, and operational life of pharmaceutical seals. Materials like PTFE and Viton offer excellent resistance to harsh chemicals and solvents used during manufacturing and cleaning procedures.

Additionally, new design enhancements—such as double lip seals, inflatable seals, and customized gasket solutions—are tailored to meet specific pressure and temperature requirements across different processing equipment.

4. Growing Pharmaceutical Production in Emerging Markets

Emerging economies in Asia-Pacific, Latin America, and the Middle East are witnessing a boom in pharmaceutical infrastructure development. As local companies ramp up manufacturing capabilities to meet domestic and export demand, the need for cost-effective yet reliable sealing solutions continues to rise.

Governments and private players in these regions are actively investing in pharmaceutical plant modernization, further bolstering market growth.

𝐄𝐱𝐩𝐥𝐨𝐫𝐞 𝐓𝐡𝐞 𝐂𝐨𝐦𝐩𝐥𝐞𝐭𝐞 𝐂𝐨𝐦𝐩𝐫𝐞𝐡𝐞𝐧𝐬𝐢𝐯𝐞 𝐑𝐞𝐩𝐨𝐫𝐭 𝐇𝐞𝐫𝐞: https://www.polarismarketresearch.com/industry-analysis/pharmaceutical-processing-seals-market

Market Challenges

1. High Cost of Advanced Sealing Materials

One of the most prominent challenges facing the market is the high cost of seals manufactured from premium materials. While these materials offer significant advantages in terms of durability and chemical resistance, the upfront investment can be prohibitive for small and medium-sized pharmaceutical manufacturers.

Especially in cost-sensitive markets, companies may struggle to balance budget constraints with compliance requirements.

2. Stringent Regulatory Hurdles

Regulatory compliance in pharmaceutical manufacturing is among the strictest across all industries. Sealing components must pass rigorous performance testing and material compatibility evaluations before being approved for use. These extended approval timelines can delay new product launches and discourage innovation.

Additionally, the increasing documentation and validation burdens placed on manufacturers add to operational complexity and cost.

Regional Analysis

North America

North America remains a dominant force in the pharmaceutical processing seals market, driven by its highly developed pharmaceutical infrastructure and strong regulatory oversight. The United States, in particular, leads in the development of biologics and high-precision pharmaceutical equipment, supporting sustained demand for advanced sealing solutions.

The region also benefits from a concentration of major players and investments in automation and cleanroom technologies.

Europe

Europe holds a significant share of the global market due to its robust pharmaceutical industry, advanced R&D facilities, and strict environmental regulations. Countries like Germany, Switzerland, and the UK are home to several top-tier pharmaceutical manufacturers and suppliers of precision components.

Sustainability concerns are also pushing European companies to adopt eco-friendly, long-lasting seals that reduce equipment downtime and product waste.

Asia-Pacific

Asia-Pacific is emerging as the fastest-growing market, led by countries such as China, India, and Japan. These nations are experiencing rapid industrialization and expansion of their pharmaceutical production capacity. The region benefits from lower manufacturing costs and government-backed healthcare initiatives.

India, in particular, is becoming a global hub for generic drug manufacturing, further fueling demand for pharmaceutical equipment seals across domestic and export facilities.

Latin America and Middle East & Africa

These regions are gradually catching up as pharmaceutical investments rise. Growing healthcare awareness, foreign direct investments, and infrastructure development are contributing to increased adoption of pharmaceutical processing seals in countries like Brazil, Mexico, UAE, and Saudi Arabia.

Key Companies

The pharmaceutical processing seals market is moderately consolidated, with several global players leading the innovation and supply chain. Key companies include:

-

Flowserve Corporation – Known for custom-engineered mechanical seals tailored to sterile environments.

-

Trelleborg AB – Offers a wide range of sealing solutions designed specifically for pharmaceutical and biotech applications.

-

Garlock (EnPro Industries) – Specializes in high-performance sealing technologies that offer resistance to aggressive chemicals and cleaning agents.

-

Saint-Gobain S.A. – A leader in material innovation, including seals for single-use systems in biopharmaceutical processes.

-

Freudenberg Group – Manufactures FDA-compliant seals and components with a focus on hygiene and durability.

-

Parker Hannifin Corporation – Offers elastomeric seals for pharmaceutical and life sciences industries, with a focus on material science and customization.

-

John Crane – Provides engineered sealing systems with a global support network.

-

IDEX Corporation – Supplies precision sealing components used in high-performance pharmaceutical equipment.

These companies are heavily investing in R&D to develop next-generation seal materials and geometries that cater to increasingly stringent industry demands.

Conclusion

The pharmaceutical processing seals market is on a strong growth trajectory, fueled by the rising demand for contamination-free manufacturing, increased biologics production, and advancements in material science. While high costs and regulatory barriers pose challenges, ongoing innovation and regional market expansion present immense opportunities for both established players and new entrants.

As global healthcare needs evolve, pharmaceutical seals will continue to serve as a critical linchpin in ensuring product safety, quality, and compliance throughout the drug development lifecycle.

More Trending Latest Reports By Polaris Market Research:

Electric Vehicle Battery Coolant Market