Carbon Prepreg Market Outlook

April 16, 2025 — Carbon Prepreg Market Poised for Expansion with Technological Advancements and Increased Industrial Applications

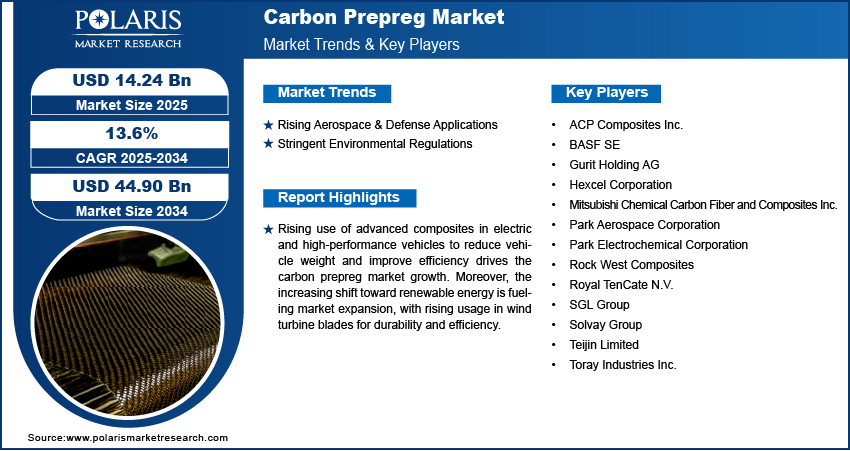

The global carbon prepreg market is poised for significant growth, driven by advancements in composite materials, increasing demand from the aerospace and automotive sectors, and the rising focus on sustainability and energy efficiency. With the demand for lightweight, high-strength materials across multiple industries, carbon prepreg is emerging as a preferred solution for manufacturers seeking to improve performance and reduce energy consumption in end products. This press release delves into the market’s growth potential, segmentation, regional outlook, and the key players leading the carbon prepreg industry.

Market Overview

Carbon prepreg refers to carbon fiber pre-impregnated with a resin matrix, which allows for easier molding and curing during manufacturing. Due to its unique combination of high tensile strength, light weight, and excellent fatigue resistance, carbon prepreg is widely used in applications where performance and durability are critical. The material is primarily used in the aerospace, automotive, sports and leisure, and wind energy industries. As industries demand greater performance and sustainability, carbon prepreg has become a valuable material solution.

The growing focus on reducing greenhouse gas emissions, coupled with the increasing demand for high-performance vehicles, lightweight aircraft, and renewable energy sources, is fueling the demand for carbon prepreg in multiple applications. Additionally, the automotive industry is rapidly adopting carbon fiber prepregs to manufacture lightweight components that improve fuel efficiency, reduce emissions, and meet regulatory standards.

The global carbon prepreg market size was valued at USD 12.54 billion in 2024 and is expected to reach USD 14.24 billion by 2025 and USD 44.90 billion by 2034, exhibiting a CAGR of 13.6% during 2025–2034.Key factors driving market growth include technological advancements in manufacturing, increasing demand from emerging economies, and rising awareness of sustainability in various industries.

Browse Full Insights:

https://www.polarismarketresearch.com/industry-analysis/carbon-prepreg-market

Key Companies in the Carbon Prepreg Market

Several leading companies are contributing to the growth of the carbon prepreg market by developing innovative products, expanding production capabilities, and establishing strategic partnerships. Some of the key players in the market include:

- Toray Industries Inc.: A leading manufacturer of carbon prepregs, Toray Industries supplies the aerospace, automotive, and renewable energy industries with high-performance prepregs. Toray’s products are known for their strength, durability, and resistance to environmental conditions.

- Hexcel Corporation: Hexcel is a global leader in carbon composite materials, including prepregs. The company provides solutions for aerospace, automotive, wind energy, and industrial applications, focusing on lightweight and high-strength materials.

- SGL Carbon: SGL Carbon is a key player in the carbon prepreg market, offering high-quality prepreg materials for aerospace, automotive, and other industries. The company is known for its innovative approach to manufacturing lightweight and durable materials.

- Solvay: Solvay is a leading chemical company that produces advanced materials, including carbon prepregs. Solvay’s carbon fiber prepreg products are widely used in aerospace, automotive, and industrial applications.

- Airex AG: Airex AG specializes in carbon fiber materials and prepregs for aerospace, automotive, and other high-performance applications. The company focuses on providing innovative, sustainable materials solutions.

- Mitsubishi Chemical Carbon Fiber and Composites, Inc.: Mitsubishi Chemical is a major producer of carbon prepregs used in the aerospace, automotive, and renewable energy sectors. The company focuses on developing lightweight, high-performance materials to meet the growing demand for carbon-based composites.

Report Scope

Carbon Prepreg Market, Resin Type Outlook (Revenue – USD Billion, 2020–2034)

- Epoxy Resin

- Phenolic Resin

- BMI Resin

- Cyanate Ester Resin

- Thermoplastic Resin

- Others

Carbon Prepreg Market, Manufacturing Process (Revenue – USD Billion, 2020–2034)

- Hot Melt Process

- Solvent Dip Process

Carbon Prepreg Market, Application Outlook (Revenue – USD Billion, 2020–2034)

- Aerospace & Defense

- Automotive

- Sports and Leisure

- Wind Energy

- Others

Carbon Prepreg Industry Developments

In July 2024, Toray announced a strategic partnership with Elevated Materials to enhance sustainability efforts by repurposing carbon fiber prepreg waste. Under the three-year agreement, Elevated Materials will transform Toray’s scrap prepreg materials into press-cured carbon fiber sheets, plates, and blocks. These repurposed products will be utilized in various industries, including sports equipment and drones, contributing to a more sustainable supply chain.

In March 2024, Mitsubishi Chemical Group introduced the BiOpreg 400 Series, an innovative carbon fiber prepreg made using plant-derived resin. The new material contains up to 25% biomass content, offering a sustainable alternative for applications in the sports, mobility, and industrial sectors. This development underscores Mitsubishi Chemical’s commitment to reducing environmental impact while maintaining high-performance standards.

In July 2022, Hexcel entered into a long-term agreement with Dassault to supply carbon fiber prepreg for the Falcon 10X program. This deal marked the first Dassault business jet program to incorporate advanced carbon fiber composites in the manufacturing of aircraft wings, reflecting the growing trend in the aerospace industry to use high-performance, lightweight materials for improved efficiency and performance.

Conclusion and Future Outlook

The carbon prepreg market is poised for significant growth over the coming years, driven by rising demand for lightweight, high-strength materials in aerospace, automotive, and renewable energy applications. The need for sustainability and energy efficiency is reshaping industrial practices, and carbon prepreg offers the perfect solution to meet these demands. Technological advancements in prepreg manufacturing, coupled with the expanding adoption of electric vehicles and renewable energy sources, are set to drive market growth.

Key players in the market are investing heavily in R&D to improve product performance and functionality, while also focusing on expanding their production capacities. As industries continue to push for more durable and sustainable solutions, the carbon prepreg market will continue to see strong demand across various sectors, ensuring a bright future for this versatile material.

More Trending Latest Reports By Polaris Market Research:

Europe Non-Automotive Rubber Transmission Belts Market

Internet Of Things (Iot) In Healthcare Market

Idiopathic Pulmonary Fibrosis Treatment Market