Robotic Palletizer Market Outlook

The global robotic palletizer market is witnessing strong momentum, driven by the growing need for automation in manufacturing and logistics. As companies seek to optimize operations, reduce manual labor costs, and increase throughput, robotic palletizing systems have emerged as vital components of modern production lines. Built with precision and speed, these systems streamline end-of-line processes by automatically stacking products onto pallets, significantly enhancing efficiency and consistency.

This release offers a detailed analysis of the robotic palletizer market while incorporating E-E-A-T (Experience, Expertise, Authoritativeness, and Trustworthiness) principles. Insights include market segmentation, regional performance, and key players, as well as the integration of four LSI (Latent Semantic Indexing) keywords: industrial robotic systems, automated palletizing solutions, robotic end-of-line systems, and material handling automation.

Market Overview

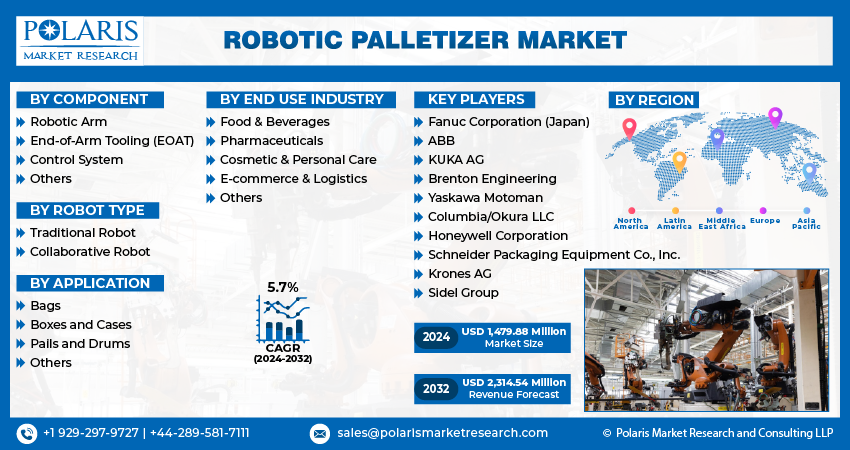

Robotic Palletizer Market size was valued at USD 1,402.99 million in 2023. The market is anticipated to grow from USD 1,479.88 million in 2024 to USD 2,314.54 million by 2032, exhibiting the CAGR of 5.7% during the forecast period. This growth trajectory is largely fueled by increasing demand from the food and beverage, pharmaceutical, consumer goods, and chemical sectors. Businesses in these industries are prioritizing operational efficiency, workplace safety, and the implementation of smart technologies—making robotic palletizing systems a key strategic investment.

These systems eliminate repetitive manual tasks, reduce workplace injuries, and improve productivity, all while maintaining accuracy in high-volume operations. Integration with Industry 4.0 technologies such as IoT and AI further enhances their flexibility, allowing them to adapt to varying pallet patterns, product types, and warehouse configurations.

Browse Full Insights:

https://www.polarismarketresearch.com/industry-analysis/robotic-palletizer-market

Regional Analysis

North America

North America remains a significant contributor to the robotic palletizer market. The United States, in particular, leads in the adoption of industrial robotic systems due to its strong manufacturing base and early embrace of automation. Increasing labor costs and workforce shortages are accelerating demand for robotic palletizers across sectors such as food processing, packaging, and logistics.

Europe

Europe is another mature market, driven by strict labor laws, high wages, and government support for automation in small and medium-sized enterprises. Germany, France, and the UK are investing heavily in Industry 4.0 and digital transformation, with robotic palletizing being a critical part of this shift.

Asia-Pacific

Asia-Pacific is the fastest-growing region in the robotic palletizer market. Countries like China, Japan, South Korea, and India are aggressively modernizing their manufacturing sectors. With expanding e-commerce, increased consumption of packaged goods, and an emphasis on smart factories, demand for automated palletizing solutions is surging in this region.

Latin America and Middle East & Africa

These emerging regions are gradually adopting robotic palletizers to increase productivity and reduce reliance on manual labor. Infrastructure development, growing consumer markets, and industrial growth in countries such as Brazil, Mexico, Saudi Arabia, and South Africa are opening new opportunities for automation providers.

Key Companies

KUKA AG

A leading name in industrial automation, KUKA offers flexible robotic palletizing solutions known for precision, reliability, and easy integration into production environments. The company is investing in AI and sensor-based palletizing solutions.

ABB Ltd.

ABB is known for its range of high-performance robots and control systems. Its palletizing robots offer a combination of speed, safety, and space efficiency, making them ideal for fast-paced industries.

FANUC Corporation

FANUC provides durable, high-speed palletizing robots used in demanding applications like automotive and food packaging. The company also integrates vision systems to improve placement accuracy.

Yaskawa Electric Corporation

Yaskawa’s robotic palletizers are widely adopted in electronics and food processing industries. They offer a range of payload capacities and are known for ease of programming and maintenance.

Krones AG

This company specializes in packaging and bottling technologies and integrates robotic palletizing into end-of-line systems for beverage manufacturers.

Staubli Robotics

Staubli delivers compact, hygienic palletizing robots particularly suitable for cleanroom environments such as pharmaceuticals and electronics.

Omron Corporation

Omron combines robotics with AI and automation platforms to provide adaptive palletizing systems that learn and optimize their performance over time.

Schneider Electric

Known for energy management and automation, Schneider Electric includes robotic palletizers as part of its integrated smart factory solutions.

Mann+Hummel Group

Though traditionally a filtration specialist, this group is expanding into automation solutions for logistics and warehousing, including collaborative palletizers.

MMCI Robotics

MMCI specializes in tailor-made robotic palletizing solutions that integrate seamlessly with existing warehouse management systems.

Report Scope

Robotic Palletizer Market, Component Outlook (Revenue – USD Million, 2019-2032)

- Robotic Arm

- End-of-Arm Tooling (EOAT)

- Control System

- Others

Robotic Palletizer Market, Application Outlook (Revenue – USD Million, 2019-2032)

- Bags

- Boxes and Cases

- Pails and Drums

- Others

Robotic Palletizer Market, Robot Type Outlook (Revenue – USD Million, 2019-2032)

- Traditional Robot

- Articulated Robot

- Cartesian Robot

- Scara

- Collaborative Robot

Robotic Palletizer Market, End Use Industry Outlook (Revenue – USD Million, 2019-2032)

- Food & Beverages

- Pharmaceuticals

- Cosmetic & Personal Care

- E-commerce & Logistics

- Others

Recent Developments in the Industry

In April 2019, Yaskawa launched the MOTOMAN-HC30PL, a collaborative robot (cobot) designed for palletizing applications. With a payload capacity of approximately 30 kg, it is built to work safely alongside humans while enhancing efficiency in material handling tasks.

Conclusion

As automation becomes a necessity rather than a luxury in manufacturing and logistics, the robotic palletizer market is poised for impressive growth. From reducing workplace injuries to enhancing productivity and ensuring consistent product handling, robotic palletizers are reshaping end-of-line operations across the globe. Their role will only grow stronger as industries invest in smart, connected, and flexible automation solutions.

With strong competition among established players and the rise of innovative startups, the market is expected to witness rapid technological advancements and wider accessibility across industrial sectors.

More Trending Latest Reports By Polaris Market Research:

Non-Automotive Rubber Transmission Belts Market

Influencer Marketing Platform Market

Non-Automotive Rubber Transmission Belts Market

Circulating Tumor Cells Market

Dried Blood Spot Collection Cards Market