The global Polybutadiene Market is on a growth trajectory, fueled by its critical role in high-performance applications, especially in synthetic rubber manufacturing. As industries prioritize durability, fuel efficiency, and cost-effectiveness, polybutadiene’s unique properties such as high abrasion resistance, low-temperature flexibility, and resilience are driving widespread adoption across sectors including tires and automotive, construction, and industrial manufacturing.

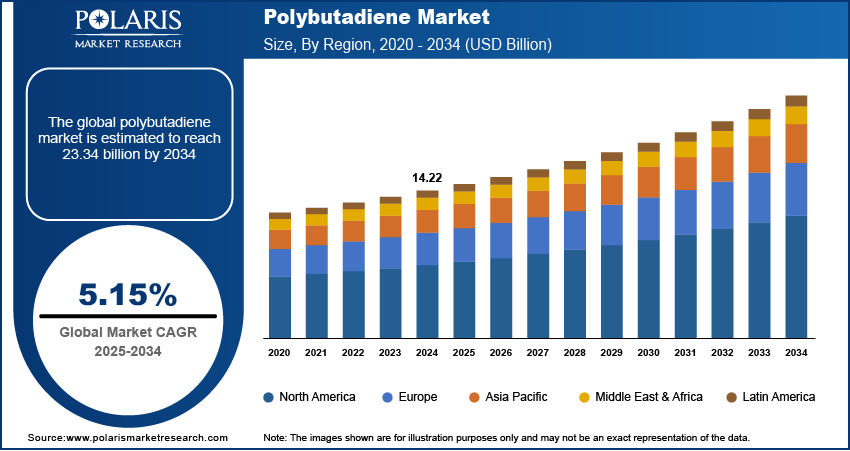

Global Polybutadiene Market size and share is currently valued at USD 14.22 billion in 2024 and is anticipated to generate an estimated revenue of USD 23.34 billion by 2034, according to the latest study by Polaris Market Research. Besides, the report notes that the market exhibits a robust 5.15% Compound Annual Growth Rate (CAGR) over the forecasted timeframe, 2025 – 2034

Market Overview

Polybutadiene is a key member of the synthetic rubber family, produced primarily through polymerization of 1,3-butadiene. It is prized for its elasticity, resilience, and resistance to wear and tear, making it one of the most widely used rubbers globally, especially in the production of tires.

There are three primary types of polybutadiene: high-cis, low-cis, and high vinyl, each offering distinct advantages depending on the end-use. The high-cis polybutadiene segment dominates the market, owing to its exceptional mechanical strength and energy efficiency benefits when used in tire manufacturing.

Polybutadiene is also extensively employed in polymer modification, where it acts as an impact modifier for plastics such as polystyrene and ABS (Acrylonitrile Butadiene Styrene), improving flexibility and durability.

Key Market Growth Drivers

1. Growing Demand in Tires and Automotive Sector

One of the most significant drivers of the polybutadiene market is its widespread application in the tires and automotive sector. Nearly 70% of global polybutadiene output is consumed in tire production, particularly in sidewalls and treads, where its high abrasion resistance helps improve fuel efficiency and tire longevity. With global vehicle production rebounding post-pandemic and the increasing popularity of electric vehicles (EVs), the demand for high-performance tires is rising, directly influencing polybutadiene consumption.

2. Expansion in Synthetic Rubber Applications

Polybutadiene is a cornerstone in synthetic rubber formulations, playing a critical role in producing high-performance products such as conveyor belts, gaskets, and hoses. Its ability to retain elasticity at low temperatures and endure repeated stress makes it indispensable in extreme operational environments. As industrialization increases in emerging markets, the consumption of synthetic rubber-based products is expected to rise in tandem.

3. Growth in Polymer Modification and Plastic Enhancement

In the plastics industry, polybutadiene is used to modify and enhance the impact resistance of brittle plastics. Its role in polymer modification is essential for improving the toughness of high-volume plastics like HIPS (High Impact Polystyrene) and ABS, which are used in appliances, electronics, and automotive interiors. With global plastics consumption projected to grow, so too is the need for robust additives like polybutadiene.

4. Advancements in Manufacturing Technologies

Advancements in catalyst systems and production processes, such as neodymium-based catalysts, are enabling manufacturers to create highly consistent polybutadiene with precise molecular structures. These innovations not only reduce production costs but also improve product quality and performance characteristics, enhancing competitiveness and spurring further adoption.

Browse Full Insights:

https://www.polarismarketresearch.com/industry-analysis/polybutadiene-market

Market Challenges

Despite the market’s strong fundamentals, several challenges could temper growth if left unaddressed:

1. Volatility in Raw Material Prices

The production of polybutadiene relies heavily on 1,3-butadiene, a derivative of crude oil. Volatility in crude oil prices can lead to unpredictable fluctuations in raw material costs, squeezing profit margins and creating supply chain uncertainty.

2. Environmental Regulations and Sustainability Concerns

Like many petroleum-derived products, polybutadiene faces scrutiny over environmental concerns, particularly regarding its non-biodegradable nature and the emissions generated during manufacturing. Stricter environmental regulations and a global push toward sustainable alternatives could pressure manufacturers to innovate or transition to greener formulations.

3. Competition from Alternative Elastomers

Polybutadiene competes with a range of other synthetic rubbers, including natural rubber, styrene-butadiene rubber (SBR), and nitrile rubber. In applications where high abrasion resistance is not a priority, other materials may be favored due to lower costs or specific performance features.

Key Company:

- China Petroleum and Chemical Corporation

- Evonik Industries

- JSR Corporation

- Kumho Petrochemical Co. Ltd

- Lanxess AG

- Lyondel Basell Industries NV

- Reliance Industries Ltd.

- Synthos S.A

- The Goodyear Tire and Rubber Company

- UBE Industries Ltd.

Market Segmentation:

Polybutadiene Market, Type Outlook (Revenue – USD Billion, 2020-2034)

- Low Cis Polybutadiene

- High Cis Polybutadiene

- High Vinyl Polybutadiene

- High Trans Polybutadiene

Polybutadiene Market, Application Outlook (Revenue – USD Billion, 2020-2034)

- Polymer Modification

- Tire Manufacturing

- Industrial Rubber Manufacturing

Regional Analysis

Asia-Pacific

Asia-Pacific is the largest and fastest-growing market for polybutadiene, accounting for over 45% of global demand. China, India, Japan, and South Korea are major hubs for tire manufacturing, plastics production, and automotive assembly. As a result, the region’s demand for synthetic rubber and related products continues to rise, supported by domestic consumption and export activity.

India, in particular, is emerging as a hotspot for polybutadiene demand due to its growing automobile industry, infrastructure investments, and increasing focus on manufacturing.

North America

The North American market is characterized by mature but stable demand, with the U.S. leading consumption due to its established automotive and industrial base. Polybutadiene is also widely used in consumer goods, sporting equipment, and plastic packaging in the region. Investments in infrastructure and innovations in polymer modification are expected to maintain moderate growth.

Europe

Europe holds a significant share in the global polybutadiene market, with Germany, France, and Italy being the primary consumers. The region’s advanced manufacturing sector, strict quality standards, and strong presence in luxury and performance vehicles contribute to consistent demand. However, the region’s ambitious environmental targets could pressure synthetic rubber manufacturers to explore bio-based alternatives.

Latin America and Middle East & Africa (MEA)

While still emerging markets, Latin America and MEA show potential due to increasing urbanization, improving living standards, and growing investments in construction and transportation. Brazil and South Africa are notable markets where the demand for durable rubber products is expanding steadily.

Future Outlook

The global polybutadiene market is expected to maintain a strong growth trajectory through 2030 and beyond, supported by industrial development, urban mobility trends, and technological innovations. Sustainability will play a pivotal role in shaping the future landscape, prompting R&D investments in recyclable and bio-based formulations.

Strategic investments in production capacity, supply chain optimization, and application development will be critical for companies aiming to stay competitive in this evolving market. Manufacturers are also expected to focus on refining product quality, reducing environmental footprints, and collaborating with tire and plastics producers to develop next-generation formulations.

More Trending Latest Reports By Polaris Market Research:

Intensity Modulated Radiotherapy Market