The global ethylene carbonate market is witnessing dynamic growth, fueled by technological advancements and expanding applications across the lithium-ion battery, polymer, and chemical industries. With the rise of electric vehicles (EVs), energy storage systems, and sustainable manufacturing practices, the demand for ethylene carbonate—a crucial carbonic acid ester—is poised to grow significantly over the next decade.

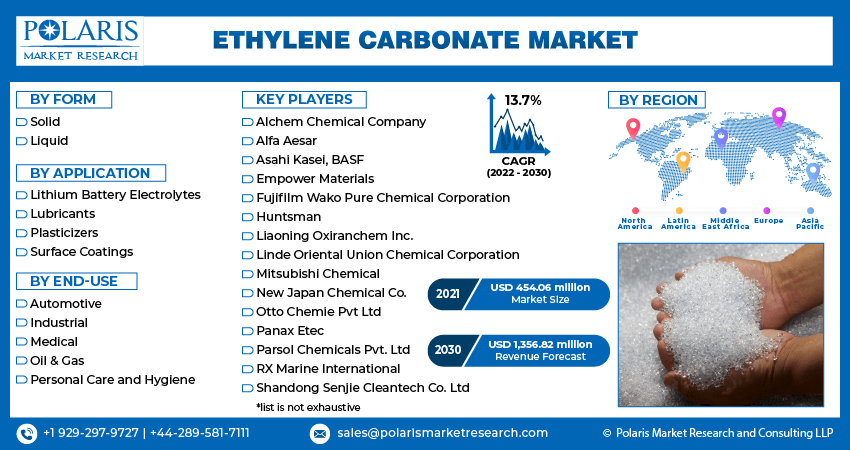

According to the research report, the global ethylene carbonate market was valued at USD 454.06 million in 2021 and is expected to reach USD 1,356.82 million by 2030, to grow at a CAGR of 13.7% during the forecast period.

Market Overview

Ethylene carbonate (C3H4O3) is a cyclic organic compound classified as a carbonic acid ester. It appears as a clear, odorless, and highly polar solvent with a relatively high boiling point and excellent thermal stability. Its defining characteristics—a high dielectric constant and low viscosity—make it particularly suitable for use as a solvent additive in electrochemical applications.

From improving battery performance to enhancing the efficacy of industrial lubricants and coatings, ethylene carbonate plays a vital role in advancing energy-efficient and environmentally friendly technologies.

Key Market Growth Drivers

1. Booming Lithium-Ion Battery Industry

The most significant driver of the ethylene carbonate market is its critical role in lithium-ion battery electrolyte formulations. As EVs gain ground globally, the need for high-energy-density batteries is expanding rapidly. Ethylene carbonate enhances ionic conductivity and solid electrolyte interphase (SEI) formation, which is essential for battery cycle life and efficiency.

With global electric vehicle sales expected to reach over 40 million units by 2030, demand for high-performance electrolytes—and hence ethylene carbonate—is projected to skyrocket.

2. Growth in Renewable Energy Storage Systems

Beyond EVs, renewable energy installations such as solar and wind require efficient energy storage solutions. Lithium-ion and emerging battery chemistries often rely on ethylene carbonate-based electrolytes for performance and safety. Governments and private investors are pouring resources into energy storage projects, directly impacting the demand for this high-performance solvent.

3. Industrial Lubricants and Coatings

Ethylene carbonate is also employed as a solvent additive in high-performance lubricants and industrial coatings. It enhances solubility and temperature resistance in these applications. With growing industrialization and the push toward sustainable formulations in the chemical industry, its use in paints, varnishes, and greases is on the rise.

4. Advancements in Polymer Manufacturing

In polymer production, especially in polycarbonate and polyester synthesis, ethylene carbonate acts as a reactant and intermediate. Its biodegradability and low toxicity make it favorable for use in environmentally conscious polymer manufacturing.

Browse Full Insights:

https://www.polarismarketresearch.com/industry-analysis/ethylene-carbonate-market

Market Challenges

While the ethylene carbonate market has robust growth prospects, it also faces several challenges that stakeholders must navigate:

1. Raw Material Dependency and Price Volatility

Ethylene carbonate is primarily synthesized through the reaction of ethylene oxide and carbon dioxide. Volatility in raw material prices, especially for ethylene oxide, can impact production costs and supply chain stability, influencing overall market pricing.

2. Toxicity Concerns and Environmental Regulations

Though ethylene carbonate is less hazardous than many industrial solvents, concerns about toxicity in high exposure environments persist. Strict regulations on chemical safety, particularly in Europe and North America, could necessitate additional investment in compliance and safety infrastructure.

3. High Purity Requirements in Battery Applications

Battery-grade ethylene carbonate must meet stringent purity standards. Even minimal contamination can affect battery performance and safety. Manufacturers face challenges in scaling production while maintaining quality assurance at the ppm (parts per million) level.

Regional Analysis

Asia-Pacific

Asia-Pacific dominates the global ethylene carbonate market, accounting for over 45% of global consumption. China, Japan, and South Korea are key players due to their advanced battery manufacturing ecosystems and dominant positions in global EV production.

China’s aggressive push toward EV adoption, supported by policy incentives and infrastructure investments, has made it the single largest consumer of battery-grade ethylene carbonate. South Korea and Japan, home to major battery producers, also contribute significantly to regional demand.

North America

North America holds the second-largest market share, driven by a rapidly growing EV sector, new battery gigafactories, and increased energy storage deployments. The U.S. government’s Inflation Reduction Act (IRA) and support for clean energy technologies are expected to boost domestic production and consumption of lithium-ion battery materials, including ethylene carbonate.

The region is also seeing growth in demand for high-performance industrial solvents and sustainable polymers.

Europe

Europe is a key player in green technology and sustainable manufacturing. Countries like Germany, France, and the Nordic nations are heavily investing in EV adoption, battery recycling, and energy storage infrastructure. Ethylene carbonate demand is increasing in tandem, supported by stringent EU regulations favoring low-emission and circular economy initiatives.

Europe’s well-established chemical industry and environmental regulations are also pushing for cleaner synthesis methods and higher-grade solvent production.

Latin America & Middle East and Africa (MEA)

These regions are in the nascent stages of market development but show promising potential. Brazil and Chile are emerging as significant players due to their lithium resources and early investments in battery production. In the Middle East and Africa, demand is growing gradually, particularly in industrial lubricants and polymer sectors.

Innovation and Strategic Developments

Greener Production Pathways

With increasing pressure to reduce carbon footprints, manufacturers are investing in eco-friendly synthesis routes for ethylene carbonate, including CO₂ utilization technologies. Carbon capture and utilization (CCU) strategies that convert industrial CO₂ into ethylene carbonate are gaining traction as a sustainable manufacturing alternative.

Battery-Grade Purification Techniques

New purification technologies, including distillation, filtration, and chromatographic methods, are being integrated into production lines to meet the ultra-high purity demands of next-generation battery systems. These techniques are enabling a consistent supply of battery-grade ethylene carbonate to meet growing global needs.

Research into Next-Generation Electrolytes

Ethylene carbonate is being explored in solid-state and hybrid electrolyte systems. Research partnerships between academic institutions and industrial R&D labs are focusing on optimizing EC compatibility with lithium-metal and sodium-ion chemistries, ensuring its relevance in future energy storage technologies.

Key Companies and Market Landscape

The ethylene carbonate market is moderately consolidated, with a handful of global producers operating at scale. Most leading players are integrated chemical manufacturers with upstream access to ethylene oxide and downstream capabilities in battery electrolyte blending, polymer additives, and high-performance coatings.

Key strategies being pursued include:

-

Capacity Expansion: To meet escalating demand, major companies are investing in new facilities in Asia and North America.

-

Sustainability Initiatives: Firms are aligning with environmental standards by adopting circular economy practices and green chemistry.

-

Strategic Partnerships: Collaborations with battery manufacturers and material science companies are enabling faster adoption of customized electrolyte solutions.

Conclusion

The ethylene carbonate market is at the heart of some of the most transformative trends of the decade—electrification, energy decentralization, and sustainable industrialization. Its role in lithium-ion battery electrolyte systems, as a solvent additive in high-performance formulations, and as a building block in advanced polymers and coatings, positions it for continued long-term growth.

As industries push for low-emission technologies and high-efficiency materials, ethylene carbonate’s unique properties—like its high dielectric constant, low toxicity, and recyclability—will keep it at the center of innovation. While challenges around safety, purity, and raw material volatility remain, technological advancements and global collaboration are expected to propel the market forward.

More Trending Latest Reports By Polaris Market Research:

Cellulosic Fire Protection Intumescent Coatings Market

Automotive Brake Systems Market