Market Overview

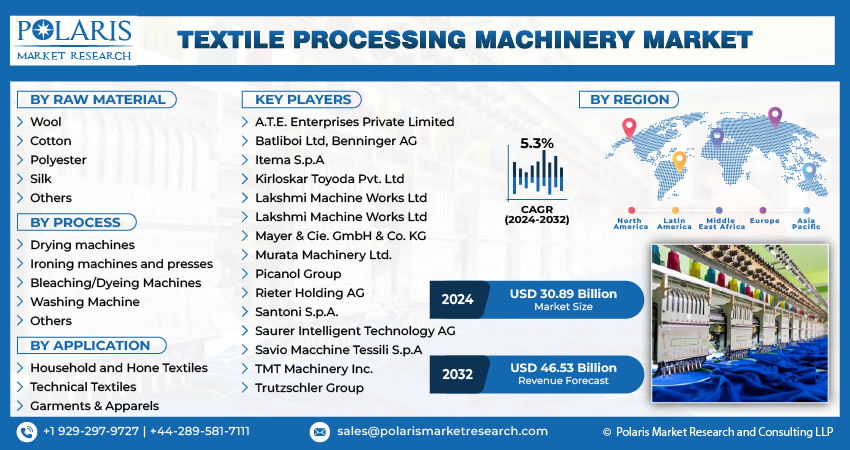

Global textile processing machinery market size and share is currently valued at USD 29.49 billion in 2023 and is anticipated to generate an estimated revenue of USD 46.53 billion by 2032 according to the latest study by Polaris Market Research. Besides, the report notes that the market exhibits a robust 5.3% Compound Annual Growth Rate (CAGR) over the forecasted timeframe, 2024 – 2032

Textile processing machinery encompasses a wide array of equipment used in the various stages of fabric treatment — from pre-treatment and dyeing to printing and finishing. These machines are essential in transforming raw textile materials into finished products suitable for commercial or industrial use. They play a critical role in altering the appearance, texture, performance, and durability of textiles.

Traditionally used by large-scale textile mills, the demand for advanced processing machines is expanding among small and medium-sized enterprises as well. Factors such as digitization, energy efficiency, and the need for eco-friendly production have prompted significant investment in innovative machinery and automation solutions across the global textile manufacturing landscape.

Growth Drivers

One of the key drivers fueling the textile processing machinery market is the growing demand for dyeing equipment and eco-friendly processing systems. As consumers and regulators alike push for sustainable fashion and lower environmental impact, manufacturers are under pressure to adopt machinery that minimizes water and chemical usage. The development of waterless dyeing technologies and digital printing machines reflects this shift toward green production.

Another significant factor is the rise of textile manufacturing in emerging economies. Countries such as India, Bangladesh, Vietnam, and Indonesia have become central hubs for global textile production, thanks to abundant labor and supportive government policies. As these regions modernize their textile sectors, demand for efficient and high-capacity machinery is rising swiftly.

Automation and digitalization are also transforming how textiles are processed. Smart textile machinery equipped with IoT, AI, and machine learning capabilities are enhancing precision, reducing downtime, and enabling predictive maintenance. These intelligent systems are not only improving operational efficiency but also helping manufacturers meet tight production schedules and high-quality standards.

The growing popularity of technical textiles and smart fabrics in sectors such as automotive, healthcare, and sportswear is further expanding the scope of textile processing. These applications require sophisticated finishing techniques and specialized machinery, particularly in the areas of coating, laminating, and digital printing.

Key Companies

The global textile processing machinery market is highly competitive and features a mix of global technology providers and region-specific manufacturers. Key companies are focusing on innovation, automation, and sustainable design to meet the changing needs of the industry.

Prominent players include:

- Itema S.p.A

- Kirloskar Toyoda Pvt. Ltd

- Lakshmi Machine Works Ltd

- Lakshmi Machine Works Ltd

- Mayer & Cie. GmbH & Co. KG

- Murata Machinery Ltd.

- Picanol Group

- Rieter Holding AG

- Santoni S.p.A.

- Saurer Intelligent Technology AG

- Savio Macchine Tessili S.p.A

- TMT Machinery Inc.

- Trutzschler Group

These companies are leading the charge in developing next-generation machinery, offering digital interfaces, real-time monitoring, and eco-efficient technologies. Collaborations, acquisitions, and partnerships are common strategies used to expand market reach and enhance technological capabilities.

𝐄𝐱𝐩𝐥𝐨𝐫𝐞 𝐓𝐡𝐞 𝐂𝐨𝐦𝐩𝐥𝐞𝐭𝐞 𝐂𝐨𝐦𝐩𝐫𝐞𝐡𝐞𝐧𝐬𝐢𝐯𝐞 𝐑𝐞𝐩𝐨𝐫𝐭 𝐇𝐞𝐫𝐞:

https://www.polarismarketresearch.com/industry-analysis/textile-processing-machinery-market

Market Segmentation

Textile Processing Machinery Market, Raw Material Outlook (Revenue – USD Billion, 2019-2032)

- Wool

- Cotton

- Polyester

- Silk

- Others

Textile Processing Machinery Market, Process Outlook (Revenue – USD Billion, 2019-2032)

- Drying machines

- Ironing machines and presses

- Bleaching/Dyeing Machines

- Washing Machine

- Others

Textile Processing Machinery Market, Application Outlook (Revenue – USD Billion, 2019-2032)

- Household and Hone Textiles

- Technical Textiles

- Garments & Apparels

Regional Analysis

The textile processing machinery market is geographically segmented into Asia-Pacific, North America, Europe, Latin America, and the Middle East & Africa.

Asia-Pacific is the dominant region in the global market, driven by a strong presence of textile manufacturing hubs in China, India, Pakistan, and Bangladesh. These countries benefit from low production costs, a large workforce, and growing investments in infrastructure and technology upgrades. Government initiatives aimed at supporting the textile industry, including modernization schemes and subsidies, are further boosting demand for advanced machinery.

Europe is focusing on sustainable textile production and high-performance technical textiles. Germany, Italy, and Switzerland are leading contributors, offering technologically advanced machinery that complies with strict environmental standards. The region is also witnessing increased adoption of automation and smart manufacturing systems.

North America is experiencing growth due to the resurgence of localized manufacturing and rising demand for high-end, customized apparel. The U.S. in particular is investing in high-tech textile machinery to support on-demand production and reduce dependency on imports.

Latin America and the Middle East & Africa are emerging as promising markets, propelled by increasing investments in textile infrastructure and growing consumer demand for affordable and diverse textile products. Countries like Brazil, Egypt, and Turkey are expanding their production capabilities, creating new opportunities for machinery manufacturers.

Conclusion

The textile processing machinery market is poised for sustained growth, backed by technological innovation, increased automation, and a global shift toward sustainable and efficient fabric treatment. As industries strive for higher productivity and environmentally responsible practices, the demand for cutting-edge machinery will continue to rise, shaping the future of textile production worldwide.

More Trending Latest Reports By Polaris Market Research: