3D Printing Metals Market Outlook

The global 3D printing metals market is witnessing a transformative shift as industries adopt metal additive manufacturing to create complex, lightweight, and high-performance components. Driven by innovations in aerospace, medical, and industrial applications, the market is poised for substantial growth, positioning 3D metal printing at the forefront of next-generation manufacturing.

As companies look for ways to reduce material waste, shorten production cycles, and enhance customization, 3D metal printing technologies such as powder bed fusion and direct energy deposition are gaining widespread traction. The convergence of digital manufacturing and high-performance metal alloys is reshaping production paradigms across sectors.

Market Overview

The 3D printing metals market involves the use of various metal powders to fabricate parts through additive processes. These processes, unlike traditional subtractive manufacturing, build objects layer-by-layer from a digital design. This not only improves material efficiency but also allows for the creation of geometrically complex structures that would be impossible or costly to achieve through conventional methods.

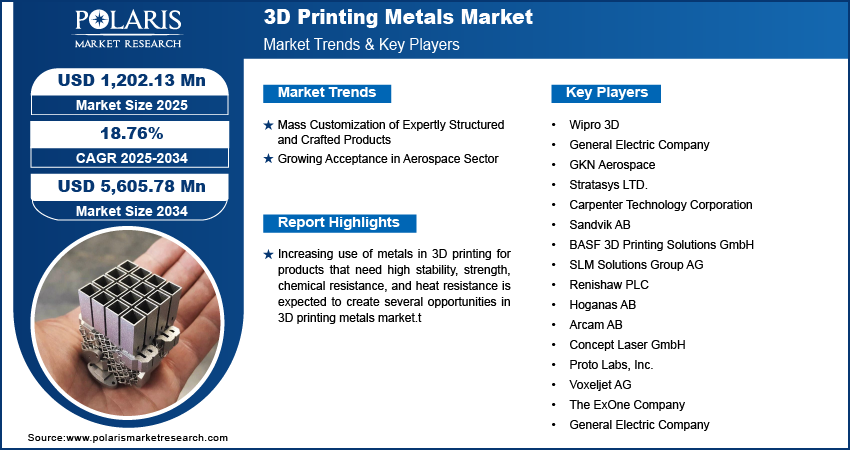

The 3D printing metals market size was valued at USD 1,014.17 million in 2024. The market is projected to grow from USD 1,202.13 million in 2025 to USD 5,605.78 million by 2034, at a CAGR of 18.7 % from 2025 to 2034. The surge in adoption is being propelled by advances in materials science, expanding industrial applications, and favorable investments in additive manufacturing technologies.

LSI Keywords Integrated:

- Metal additive manufacturing

- Powder bed fusion

- Aerospace 3D printing

- Direct energy deposition

Report Scope

3D Printing Metals Market, Form Type Outlook (Revenue – USD Million, 2020-2034)

- Powder

- Filament

- Others

3D Printing Metals Market, Product Outlook (Revenue – USD Million, 2020-2034)

- Titanium

- Aluminum

- Stainless Steel

- Nickel

- Others

3D Printing Metals Market, Technology Outlook (Revenue – USD Million, 2020-2034)

- Directed Energy Deposition

- Sheet Lamination

- Binder Jetting

- Powder Bed Fusion

- Metal Extrusion

- Others

3D Printing Metals Market, End User Outlook (Revenue – USD Million, 2020-2034)

- Aerospace & Defense

- Consumer Electronics

- Automotive

- Construction

- Healthcare

- Others

Browse Full Insights:https://www.polarismarketresearch.com/industry-analysis/3d-printing-metal-market

Regional Analysis

North America:

North America, especially the United States, dominates the 3D printing metals market due to early technology adoption, a strong aerospace and defense industry, and significant R&D investments. Government support and private-public partnerships further bolster the region’s leadership in metal additive manufacturing.

Europe:

Europe is a mature market, led by countries like Germany, the UK, and France. The presence of major aerospace companies, automotive manufacturers, and academic research institutions drives innovation and commercialization of 3D printing metals.

Asia-Pacific:

Asia-Pacific is experiencing the fastest growth, driven by industrial expansion in China, Japan, and South Korea. Governments in the region are investing in advanced manufacturing initiatives and training programs to foster domestic capabilities in 3D metal printing.

Latin America and Middle East & Africa:

These regions are emerging markets, increasingly adopting 3D printing for automotive, energy, and medical applications. Brazil, UAE, and South Africa are key players investing in digital manufacturing infrastructure.

Key Companies in the 3D Printing Metals Market

The 3D printing metals market is competitive and rapidly evolving. Leading players are focusing on expanding production capacity, forming strategic alliances, and advancing metal powder quality and printing technologies.

- EOS GmbH

- A pioneer in industrial 3D printing, EOS specializes in metal and polymer systems. Its Direct Metal Laser Sintering (DMLS) technology is widely adopted in aerospace and healthcare.

- 3D Systems Corporation

- One of the earliest entrants in the market, 3D Systems offers solutions ranging from prototyping to end-use parts across various metal types. It serves sectors including aerospace, automotive, and dental.

- SLM Solutions

- Based in Germany, SLM Solutions focuses on selective laser melting and high-performance printing systems suitable for heavy industrial use.

- GE Additive

- A subsidiary of General Electric, GE Additive offers integrated solutions that include 3D printers, metal powders, and engineering support. It has strong ties to aerospace and power industries.

- Renishaw plc

- UK-based Renishaw provides advanced metal additive manufacturing systems, particularly for medical implants and dental prosthetics.

- Desktop Metal

- Known for its cost-effective systems, Desktop Metal targets small and mid-sized businesses with binder jetting technology and office-friendly metal printers.

- Hoganas AB

- A major metal powder supplier, Hoganas plays a crucial role in raw material development for 3D printing, including alloy customization and powder refinement.

Emerging Trends and Innovations

- Advanced Alloys Development: Manufacturers are developing new metal powders optimized for printability, mechanical strength, and corrosion resistance. These include high-entropy alloys and customized composites.

- Hybrid Manufacturing: Combining additive and subtractive processes offers precision and scalability for industries like aerospace and tooling.

- Digital Workflow Integration: End-to-end digital platforms that integrate CAD, simulation, and quality assurance are improving production speed and accuracy.

- Sustainability Focus: Metal additive manufacturing enables low-waste production and the recycling of unused powder, aligning with circular economy initiatives.

- Certification and Standardization: Efforts are underway to create global standards for metal 3D printed parts, especially in safety-critical industries like aviation and healthcare.

Challenges in the Market

Despite rapid advancement, the 3D printing metals market faces several obstacles:

- High Cost of Equipment and Materials: Metal printers and premium alloys require significant capital investment, which can be a barrier for small enterprises.

- Material Qualification and Part Certification: Industries like aerospace demand rigorous testing and validation before adopting printed components, slowing down deployment.

- Limited Skilled Workforce: The lack of trained professionals in metal additive design, operation, and post-processing remains a challenge in many regions.

However, ongoing training programs, government grants, and increased academic-industry collaboration are helping address these gaps.

3D Printing Metals Industry Developments

In July 2024, 3D Systems and Precision Resource formed a strategic partnership aimed at advancing metal additive manufacturing and accelerating its adoption in high-criticality applications.

In November 2023, Materialise and Nikon SLM Solutions announced a collaboration to develop customized Build Processors for Nikon SLM Solutions’ printers. These Build Processors will be fully integrated into the Materialise CO-AM platform, enhancing compatibility and performance.

Conclusion

The 3D printing metals market represents a frontier of manufacturing innovation, enabling lightweight design, rapid prototyping, and customized production across high-value industries. With breakthroughs in powder bed fusion, direct energy deposition, and metal powder development, metal additive manufacturing is poised to redefine production standards.

The continued integration of aerospace 3D printing, coupled with regional efforts to build advanced manufacturing infrastructure, ensures a bright future for this sector. As cost-efficiency improves and industry standards mature, 3D metal printing is set to become a cornerstone of modern industrial strategy.

More Trending Latest Reports By Polaris Market Research:

Aircraft Hydraulic Systems Market

Microfiltration Membranes Market

Brewery Equipment Market: Methodical and Commercial Systems for Efficient Beer Brewing