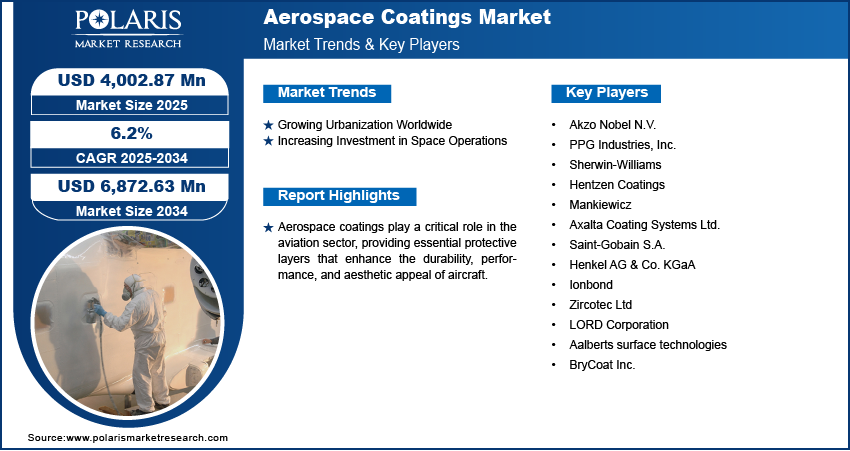

The global aerospace coatings market is experiencing accelerated growth, fueled by the surge in air travel, rising production of commercial and military aircraft, and growing focus on advanced surface protection technologies. The global aerospace coatings market size is expected to reach USD 6,872.63 million by 2034, according to a new study by Polaris Market Research.

Market Overview

Aerospace coatings are high-performance solutions engineered to protect aircraft from harsh environments, corrosion, UV radiation, and extreme temperatures. These coatings improve aerodynamics, enhance aesthetics, and reduce maintenance downtime by shielding critical components. With the increasing complexity and cost of modern aircraft, the demand for effective aircraft surface coatings has become indispensable across the aviation value chain.

The market is witnessing a shift toward water-based and chrome-free formulations as manufacturers align with global sustainability standards. These next-generation coatings not only meet environmental compliance but also deliver exceptional durability, color retention, and resistance to abrasion. The growth trajectory is being reinforced by the resurgence of air travel, expansion of military aircraft fleets, and technological advancements in aerospace paint systems.

𝐆𝐞𝐭 𝐄𝐱𝐜𝐥𝐮𝐬𝐢𝐯𝐞 𝐒𝐚𝐦𝐩𝐥𝐞 𝐏𝐚𝐠𝐞𝐬 𝐨𝐟 𝐓𝐡𝐢𝐬 𝐑𝐞𝐩𝐨𝐫𝐭: https://www.polarismarketresearch.com/industry-analysis/aerospace-coatings-market/request-for-sample

Key Market Growth Drivers

1. Expansion of Commercial Aviation

The rapid increase in passenger air traffic and fleet expansion by airlines across developing economies has created significant demand for protective coatings. Aircraft manufacturers are ramping up production of new narrow-body and wide-body aircraft to meet regional and international demand. As these fleets grow, the need for both OEM and maintenance coatings grows proportionally.

2. Advancements in Coating Technologies

Innovation in corrosion-resistant aerospace coatings has enabled manufacturers to develop lightweight, highly durable coatings that reduce drag and fuel consumption. Nanotechnology, smart coatings, and fluoropolymer-based systems are revolutionizing performance, particularly for high-altitude aircraft operating under severe environmental stress.

3. Military Modernization Programs

Governments are heavily investing in defense modernization, which includes upgrading aging fleets and producing advanced fighter jets, helicopters, and UAVs. Military aircraft coatings, in particular, must withstand extreme weather, chemical exposure, and combat scenarios. This sector is a significant contributor to the rising demand for high-performance and stealth-compatible coatings.

4. MRO and Aftermarket Growth

With a large number of aging aircraft still in service, maintenance, repair, and overhaul (MRO) operations are expanding. Routine repainting and surface refurbishment are key components of MRO activities, making aftermarket aerospace paint systems a major segment of the market.

Market Segmentation

By Product Type Outlook (Volume, Tons; Revenue, USD Million, 2020 – 2034)

- Top-coat

- Primer

- Others

By Resin Type Outlook (Volume, Tons; Revenue, USD Million, 2020 – 2034)

- Polyurethanes

- Epoxy

- Others

By Technology Outlook (Volume, Tons; Revenue, USD Million, 2020 – 2034)

- Liquid Coating

- Powder Coating

- Others

By End User Outlook (Volume, Tons; Revenue, USD Million, 2020 – 2034)

- MRO

- OEM

By Application Outlook (Volume, Tons; Revenue, USD Million, 2020 – 2034)

- Exterior

- Interior

By Aviation Type Outlook (Volume, Tons; Revenue, USD Million, 2020 – 2034)

- Commercial Aviation

- Military Aviation

- General Aviation

- Others

Quick Buy @ https://www.polarismarketresearch.com/buy/172/0

Regional Analysis

North America:

North America remains the largest market, owing to its advanced aerospace manufacturing ecosystem and substantial defense spending. The United States is home to key aircraft OEMs and defense contractors who consistently invest in innovative coating systems for both commercial and military use.

Europe:

With major aerospace hubs in Germany, France, and the U.K., Europe holds a significant market share. The region’s stringent environmental regulations are pushing the adoption of water-based and chrome-free coatings, fostering innovation in sustainable aerospace solutions.

Asia-Pacific:

This region is the fastest-growing market, led by countries like China, India, and Japan. Rising domestic air travel, growing defense budgets, and the emergence of local aircraft manufacturing initiatives are accelerating demand. Expansion of MRO facilities across Southeast Asia is also a key contributor.

Middle East & Africa:

The region’s growing airline industry, particularly in the UAE and Saudi Arabia, is driving demand for coatings used in both OEM and aftermarket applications. Meanwhile, countries in Africa are beginning to modernize their aviation infrastructure, presenting long-term opportunities.

Latin America:

Growth in this region is supported by increasing investments in regional aviation and the expansion of budget airlines. Brazil, with its active aerospace sector, plays a pivotal role in regional coating demand.

𝐄𝐱𝐩𝐥𝐨𝐫𝐞 𝐓𝐡𝐞 𝐂𝐨𝐦𝐩𝐥𝐞𝐭𝐞 𝐂𝐨𝐦𝐩𝐫𝐞𝐡𝐞𝐧𝐬𝐢𝐯𝐞 𝐑𝐞𝐩𝐨𝐫𝐭 𝐇𝐞𝐫𝐞:https://www.polarismarketresearch.com/industry-analysis/aerospace-coatings-market

Key Companies

Several global players are leading the aerospace coatings market with advanced technologies, strategic partnerships, and strong distribution networks. Key companies include:

-

AkzoNobel N.V. – A global leader in sustainable coatings, offering a broad portfolio of exterior and interior aircraft coatings.

-

PPG Industries Inc. – Known for innovative aerospace coating systems used by leading aircraft manufacturers and MROs worldwide.

-

Sherwin-Williams Company – Provides a comprehensive range of aerospace paint systems, including primers and topcoats for commercial and military aircraft.

-

Axalta Coating Systems – Offers lightweight, eco-efficient coating solutions with a focus on operational efficiency and reduced emissions.

-

Hentzen Coatings, Inc. – Specializes in military aircraft coatings with proven performance in extreme conditions.

-

Henkel AG & Co. KGaA – Supplies functional coatings, sealants, and surface treatments for aircraft manufacturing and maintenance.

-

Mankiewicz Coatings – Recognized for high-performance interior and exterior coatings tailored to meet stringent aviation standards.

These companies are increasingly investing in R&D to create environmentally compliant and cost-effective solutions while expanding their footprint across emerging markets.

Conclusion and Future Outlook

The aerospace coatings market is on a growth trajectory supported by rising air traffic, technological innovation, and increasing defense investments. The ongoing transformation toward eco-friendly and high-performance coating systems is opening new avenues for players in the sector.

With sustainability, fuel efficiency, and durability emerging as the core focus areas, the future of aerospace coatings lies in smart, multifunctional systems that go beyond traditional protective roles. From commercial jets to unmanned aerial vehicles, the demand for next-gen coatings is poised to skyrocket, making this market one of the most dynamic segments within the global aviation industry.

More Trending Latest Reports By Polaris Market Research:

Non-Automotive Rubber Transmission Belts Market

Treasury Management System Market

Automotive Lightweight Material Market