Market Overview

Wafer processing equipment forms the backbone of semiconductor device fabrication. These machines facilitate the critical steps in turning silicon wafers into functioning microchips, including photolithography, etching, cleaning, and deposition processes. Innovations in miniaturization and chip design, particularly in logic and memory semiconductors, are intensifying the need for sophisticated equipment capable of working at atomic-level precision.

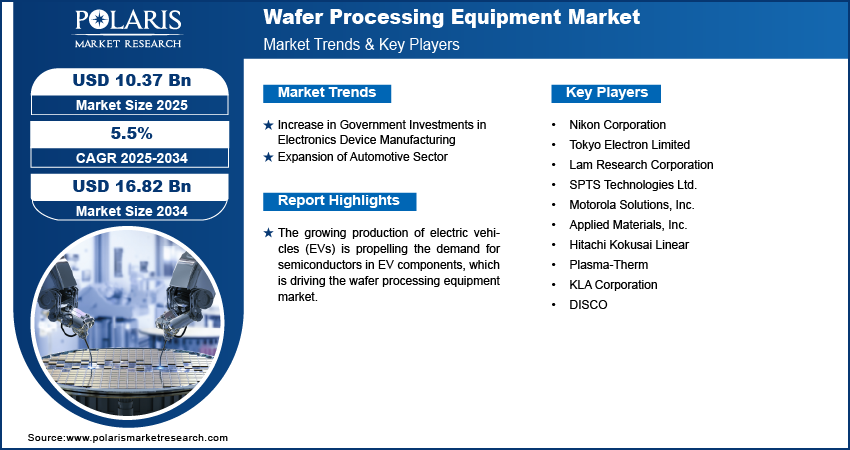

The escalating investments in 5G infrastructure, artificial intelligence (AI), and Internet of Things (IoT) technologies are fueling semiconductor consumption, thereby boosting demand for wafer processing solutions. Moreover, the global shift toward electric vehicles (EVs) and autonomous driving is generating additional momentum for the market, as automotive-grade chips require high-performance wafer fabrication.

Global Wafer Processing Equipment Market size and share is currently valued at USD 9.83 billion in 2024 and is anticipated to generate an estimated revenue of USD 16.82 billion by 2034, according to the latest study by Polaris Market Research. Besides, the report notes that the market exhibits a robust 5.5% Compound Annual Growth Rate (CAGR) over the forecasted timeframe, 2025 – 2034.

Market Segmentation

The wafer processing equipment market can be segmented based on equipment type, wafer size, end-user, and application.

Wafer Processing Equipment Market, Process Outlook

- Deposition

- Etch

- Mass Technology

- Strip and Clean

Wafer Processing Equipment Market, Applications Outlook

- Grinding and Probing

- Polishing

- Edge Shaping

- Cleaning

- Dicing

Wafer Processing Equipment Market, End Users Outlook

- Computer

- Communication

- Consumer

- Industrial

- Others

Browse more: https://www.polarismarketresearch.com/industry-analysis/wafer-processing-equipment-market

Regional Analysis

North America:

North America remains a crucial hub for wafer processing equipment due to its strong semiconductor design ecosystem and active government support for reshoring chip manufacturing. Substantial R&D investments and technological leadership in advanced lithography and process control tools continue to underpin regional growth.

Asia-Pacific:

Asia-Pacific leads the global market in both consumption and manufacturing of semiconductor equipment. Nations like South Korea, Taiwan, Japan, and China have made extensive investments in fabrication infrastructure. Favorable government policies, combined with the presence of major fabs, support the region’s continued dominance.

China’s drive for semiconductor self-reliance has intensified investment in domestic fabrication capabilities, bolstering demand for a wide array of wafer processing systems. Meanwhile, Taiwan and South Korea remain leaders in advanced node manufacturing, heavily investing in EUV photolithography and cleanroom upgrades.

Europe:

Europe is increasingly emphasizing semiconductor sovereignty, driven by strategic needs in automotive and aerospace sectors. The European Union’s initiatives to boost local chip production have led to rising demand for both front-end and back-end processing equipment. Focus on green manufacturing practices is also fostering innovation in energy-efficient and sustainable equipment designs.

Middle East & Africa:

Although still in nascent stages, the Middle East is gradually entering the semiconductor value chain through partnerships and technological investments. Initiatives aimed at diversifying national economies away from oil dependency may contribute to modest regional growth in the medium term.

Latin America:

Limited but growing participation in electronics manufacturing and assembly, particularly in Brazil and Mexico, provides niche opportunities for wafer processing equipment suppliers, especially those focused on legacy nodes and support systems.

Key Companies and Market Landscape

The wafer processing equipment market is characterized by high capital intensity and rapid technological change. Market players focus heavily on research and development to maintain competitive advantages, particularly in next-generation lithography, etching precision, and contamination control. Strategic collaborations, mergers, and capacity expansion remain essential tactics to cater to shifting demand patterns and geopolitical dynamics.

Technological breakthroughs, such as high-numerical-aperture (High-NA) EUV lithography and advanced metrology tools, are redefining what is possible in sub-5nm chip manufacturing. Additionally, firms are investing in modular, scalable systems to allow for quicker adaptation to evolving fab requirements.

Another growing trend is the integration of AI and machine learning into equipment operation and diagnostics. These enhancements not only improve process yields but also facilitate predictive maintenance, thereby increasing equipment uptime and production efficiency.

Workforce training and sustainability are also becoming pivotal strategic priorities. As cleanroom technology becomes more complex, manufacturers are creating partnerships with academic institutions to ensure a pipeline of skilled technicians. Furthermore, innovations in energy recycling, chemical reuse, and dry processing techniques are reducing the environmental footprint of wafer production facilities.

Outlook and Future Trends

The wafer processing equipment market is expected to continue on a strong growth trajectory through the end of the decade. According to industry projections, the market is likely to surpass significant valuation thresholds as AI, 6G, quantum computing, and next-gen automotive systems move from R&D to commercial scale.

Future demand will likely be driven by:

- Proliferation of smart devices and sensors in everyday life.

- Adoption of advanced logic nodes below 3nm.

- Expansion of semiconductor fabs in emerging regions.

- Increased investment in domestic semiconductor capabilities by governments worldwide.

Challenges such as supply chain disruptions, geopolitical tensions, and high R&D costs could influence short-term dynamics, but the long-term outlook remains highly positive.

Conclusion

As digitalization accelerates across industries, the global Wafer Processing Equipment Market stands as a critical enabler of technological progress. Innovations in photolithography systems, etching equipment, and cleanroom technology will continue to drive performance improvements and cost-efficiencies in semiconductor manufacturing. With strong demand emerging from every corner of the globe, the industry is entering a transformative phase poised for sustained growth and evolution.

More Trending Latest Reports By Polaris Market Research:

Pre-owned Luxury Watches Market

U.S. Renewable Methanol Market