Market Overview

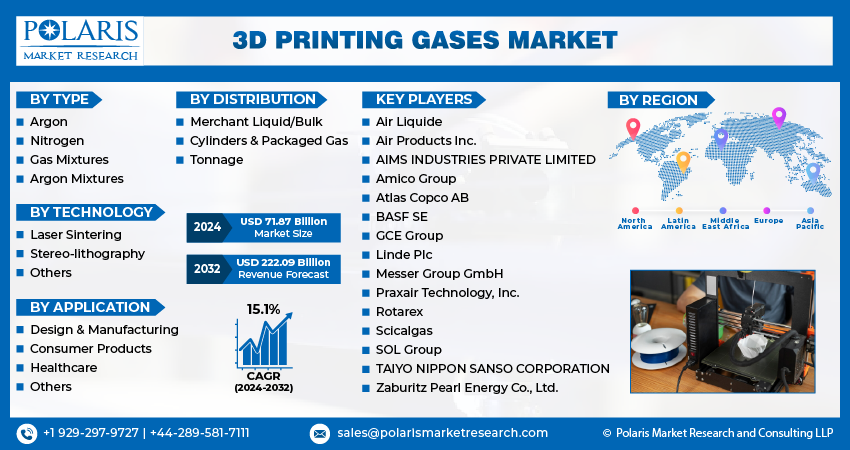

Global 3D Printing Gases Market size and share is currently valued at USD 62.49 billion in 2023 and is anticipated to generate an estimated revenue of USD 222.09 Billion by 2032, according to the latest study by Polaris Market Research. Besides, the report notes that the market exhibits a robust 15.1% Compound Annual Growth Rate (CAGR) over the forecasted timeframe, 2024 – 2032.

3D printing gases are integral to various additive manufacturing processes, especially those involving metals, polymers, and resins. These gases serve multiple purposes: maintaining a controlled atmosphere to prevent oxidation, improving printing resolution, enhancing material fusion, and stabilizing reactive materials during production. The gases most commonly used include argon, nitrogen, helium, and a variety of gas mixtures tailored to specific 3D printing applications.

Key Market Growth Drivers

- Expansion of Additive Manufacturing Across Industries

The rise of additive manufacturing as a mainstream production method is the most significant driver of the 3D printing gases market. Industries such as aerospace, defense, medical, and automotive are rapidly adopting 3D printing to create complex geometries, reduce material waste, and shorten lead times. As these sectors grow increasingly reliant on high-performance 3D printing processes, the demand for specialized gases used in sintering, melting, and post-processing also increases.

- Rise in Metal 3D Printing Applications

Metal 3D printing, including direct metal laser sintering (DMLS), electron beam melting (EBM), and binder jetting, requires stringent control of atmospheric conditions. Inert gases such as argon and nitrogen are critical to preventing oxidation and contamination during the printing process. The high-value end-use applications in aerospace and medical implants are further elevating the need for precision and consistency in gas usage.

- Need for Ultra-High Gas Purity

With manufacturers pushing the limits of 3D printing performance, maintaining gas purity has become essential. Impurities in gases can lead to part deformation, microstructural defects, and compromised mechanical properties. As a result, there is a growing trend toward using ultra-high purity gases, especially in applications that demand tight tolerances and regulatory compliance, such as in healthcare and defense sectors.

- Advancements in Gas Handling and Distribution Systems

Technological advancements in gas distribution, storage, and flow control systems are making it easier to ensure consistent supply and purity during 3D printing processes. Automated monitoring, leak detection, and digital control interfaces are enabling real-time regulation of gas flow, pressure, and composition—further boosting the reliability and efficiency of the manufacturing process.

- Government and Private Sector Investment

Governments across the globe are investing in 3D printing R&D initiatives as part of Industry 4.0 and smart manufacturing strategies. Concurrently, private sector players are pouring capital into 3D printing infrastructure, including gas supply chains, which supports overall market growth. Partnerships between gas manufacturers and 3D printing solution providers are also fueling innovation and integrated service offerings.

Browse Full Insights:

https://www.polarismarketresearch.com/industry-analysis/3d-printing-gases-market

Market Challenges

Despite the market’s rapid ascent, several challenges must be addressed for sustained growth.

- High Cost of High-Purity Gases

Producing and maintaining ultra-high gas purity involves significant costs in purification, storage, and transport. These costs can deter smaller manufacturers from adopting optimal gas conditions, especially in price-sensitive markets.

- Technical Complexity of Metal 3D Printing

While metal 3D printing offers substantial benefits, it is technically complex and highly sensitive to changes in gas flow and composition. Maintaining the precise environmental parameters requires skilled operators, expensive monitoring systems, and highly controlled facilities.

- Lack of Standardization

There is currently no universal standard for 3D printing gas specifications across industries or geographies. This creates confusion and inconsistency, particularly for companies operating across multiple regions or serving different sectors. A lack of standards also complicates the certification and quality assurance process.

- Environmental Concerns

While inert gases like argon are abundant and generally safe, others like helium are limited in supply and increasingly expensive. Additionally, the extraction and handling of some industrial gases have environmental implications that could lead to regulatory scrutiny or sustainability concerns.

Regional Analysis

North America

North America holds the largest share of the global 3D printing gases market, owing to its early adoption of additive manufacturing and robust presence of aerospace and defense industries. The United States is home to numerous research institutions, 3D printing startups, and advanced manufacturing hubs that rely heavily on metal 3D printing processes. This, in turn, sustains high demand for high-purity inert gases.

Europe

Europe is a mature and technologically advanced market, particularly in Germany, France, and the UK. The region benefits from strong government support for Industry 4.0 initiatives, with a growing emphasis on sustainability and precision manufacturing. The European aerospace and automotive sectors have been key adopters of metal 3D printing, boosting demand for argon, nitrogen, and specialized gas mixtures.

Asia-Pacific

Asia-Pacific is witnessing the fastest growth in the 3D printing gases market. Countries like China, Japan, South Korea, and India are investing heavily in 3D printing infrastructure and technology to enhance manufacturing competitiveness. As companies in this region shift from prototyping to full-scale production, demand for ultra-pure gases and advanced handling systems is increasing rapidly.

Middle East & Africa

Although smaller in size, the Middle East & Africa region is beginning to show interest in 3D printing, especially in the energy, construction, and healthcare sectors. Government-backed technology hubs and free zones in the UAE and Saudi Arabia are fostering innovation, including investment in metal additive manufacturing, thereby stimulating gas demand.

Latin America

Latin America is in the early stages of 3D printing adoption, but its manufacturing sector is expected to embrace the technology in coming years. Brazil and Mexico show potential due to increasing industrial activity and a growing interest in advanced production technologies.

Key Companies

Leading companies in the 3D printing gases market are driving innovation through research, strategic partnerships, and investments in high-purity gas technologies. These firms are focusing on improving gas delivery systems, enhancing supply chain reliability, and expanding their reach into emerging markets. Some companies also offer end-to-end services, including gas storage, monitoring equipment, and training to help manufacturers optimize gas use.

- Air Liquide

- Air Products Inc.

- AIMS INDUSTRIES PRIVATE LIMITED

- Amico Group

- Atlas Copco AB

- BASF SE

- GCE Group

- Linde Plc

- Messer Group GmbH

- Praxair Technology, Inc.

- Rotarex

- Scicalgas

- SOL Group

- TAIYO NIPPON SANSO CORPORATION

- Zaburitz Pearl Energy Co., Ltd.

Conclusion

The 3D Printing Gases Market stands at a pivotal moment of growth, fueled by the expanding application of additive manufacturing, particularly in high-stakes industries like aerospace, healthcare, and automotive. As the demand for metal 3D printing and high-precision output grows, so does the importance of atmospheric control and gas purity.

More Trending Latest Reports By Polaris Market Research: