Market Overview

The global caprolactam market is witnessing a robust surge in demand, underpinned by the material’s pivotal role in the production of Nylon-6 fibers and resins. Caprolactam, an organic compound primarily used as a monomer in the synthesis of synthetic fibers, is gaining traction across a variety of end-use industries including textiles, automotive, electronics, and industrial applications. With global industries accelerating their shift towards lightweight, high-performance, and sustainable materials, the caprolactam market is projected to witness significant expansion over the next decade.

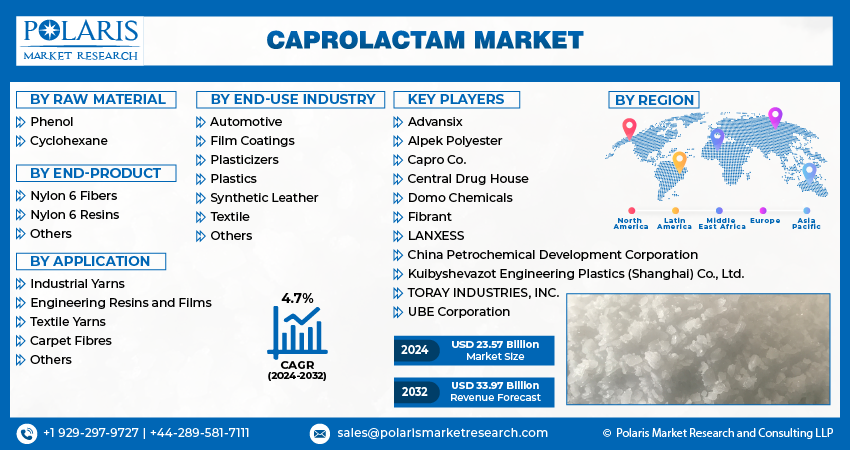

Global caprolactam market size and share is currently valued at USD 23.57 billion in 2024 and is anticipated to generate an estimated revenue of USD 33.97 billion by 2032 according to the latest study by Polaris Market Research. Besides, the report notes that the market exhibits a robust 4.7% Compound Annual Growth Rate (CAGR) over the forecasted timeframe, 2024 – 2032.

Key Market Drivers

The primary driver of the caprolactam market is the increasing demand for Nylon-6, a versatile polymer known for its strength, elasticity, and resistance to abrasion and chemicals. Nylon-6 is extensively used in sectors such as:

- Textiles and Apparel: Due to its lightweight nature and durability, Nylon-6 is preferred for making hosiery, sportswear, and swimwear.

- Automotive: Caprolactam-based Nylon-6 is used in under-the-hood applications and interior components due to its thermal stability and mechanical strength.

- Electrical & Electronics: The insulating properties of Nylon-6 make it ideal for connectors, switches, and other electronic components.

Moreover, growing emphasis on circular economy models and sustainable product development is prompting manufacturers to explore bio-based caprolactam and more efficient catalytic processes to minimize environmental impacts.

Market Segmentation

Caprolactam Market, Raw Material Outlook (Revenue – USD Billion, 2019-2032)

- Phenol

- Cyclohexane

Caprolactam Market, Application Outlook (Revenue – USD Billion, 2019-2032)

- Industrial Yarns

- Engineering Resins and Films

- Textile Yarns

- Carpet Fibres

- Others

Caprolactam Market, End-Product Outlook (Revenue – USD Billion, 2019-2032)

- Nylon 6 Fibers

- Nylon 6 Resins

- Others

Browse more:https://www.polarismarketresearch.com/industry-analysis/caprolactam-market

Regional Analysis

North America:

North America represents a mature yet innovative caprolactam market, with a strong focus on research and development to improve yield and reduce waste. Regulatory compliance and demand for high-quality engineering plastics in automotive and aerospace sectors continue to drive regional growth.

Europe:

Europe is actively moving towards eco-friendly alternatives, including bio-based caprolactam. Strict environmental regulations, especially in Western European countries, are accelerating the adoption of sustainable production techniques. The region also has a significant demand for Nylon-6 in automotive and industrial components.

Asia-Pacific:

Asia-Pacific dominates the global caprolactam market, accounting for more than half of the global consumption. The region benefits from a strong manufacturing base, growing textile exports, and booming automotive production. Countries such as China, India, Japan, and South Korea are major hubs for caprolactam manufacturing and consumption.

China, in particular, has invested heavily in caprolactam plants and Nylon-6 polymerization facilities. Meanwhile, India’s textile industry is one of the fastest growing sectors contributing to caprolactam demand. The favorable economic landscape and government support for industrialization further enhance regional market dynamics.

Latin America:

Latin America is experiencing moderate growth in the caprolactam market, driven by increasing demand in the automotive and consumer goods sectors. Brazil and Mexico are the leading contributors, benefitting from improving industrial infrastructure and rising domestic consumption.

Middle East & Africa:

Although the Middle East & Africa currently hold a smaller market share, the region is expected to see gradual growth. Investments in industrial development, especially in Gulf countries, are likely to create opportunities for caprolactam suppliers, particularly in the form of Nylon-6 resins for construction and infrastructure.

Sustainability and Innovation in Caprolactam Production

A key trend shaping the future of the caprolactam market is the increasing focus on green chemistry. Innovations in catalyst systems, process intensification, and waste heat recovery are driving efficiency in caprolactam production. Additionally, several pilot projects are exploring microbial fermentation and biomass-based routes to create bio-caprolactam with a lower carbon footprint.

Another promising development is the recycling of Nylon-6 through depolymerization techniques, enabling the recovery of caprolactam from post-consumer products. This closed-loop model supports both environmental goals and economic efficiency.

Competitive Landscape

The global caprolactam market is moderately consolidated, with a mix of global chemical enterprises and regional players. These companies are actively engaging in strategic initiatives such as:

- Expanding production capacities to meet growing demand in Asia-Pacific

- Collaborating with textile and automotive OEMs to create high-performance applications

- Investing in R&D for eco-friendly and cost-efficient production routes

There is also a trend of vertical integration, where caprolactam producers are entering downstream markets such as Nylon-6 fiber and resin manufacturing to gain greater control over the value chain.

Challenges and Restraints

Despite its promising outlook, the caprolactam market faces several challenges:

- Volatile Raw Material Prices: Price fluctuations in crude oil-derived feedstocks like cyclohexane and phenol can impact production costs.

- Environmental Regulations: Stringent regulations around emissions and waste management necessitate investments in cleaner production technologies.

- Substitution by Alternatives: In certain applications, Nylon-6 faces competition from alternatives like polypropylene and polyester.

However, continuous innovation and the rising global emphasis on sustainability are expected to help the industry mitigate these challenges effectively.

Future Outlook

The global caprolactam market is on a trajectory of strong and sustained growth. The rising demand for Nylon-6 in textiles, automotive, and engineering plastics, combined with ongoing advancements in production technology, positions caprolactam as a vital industrial chemical over the coming decade. As stakeholders continue to prioritize sustainability, bio-based caprolactam and circular economy strategies will likely redefine market dynamics and foster long-term resilience.

Emerging economies in Asia-Pacific and Latin America will play a key role in shaping global demand, while established markets in North America and Europe will focus on innovation and regulatory compliance. Collectively, these trends are expected to create a balanced, diversified, and opportunity-rich caprolactam market well in the future.

More Trending Latest Reports By Polaris Market Research:

Traffic Road Marking Coating Market

Building Better Futures: How MDI Manufacturers Are Redefining Foam Insulation