Market Overview:

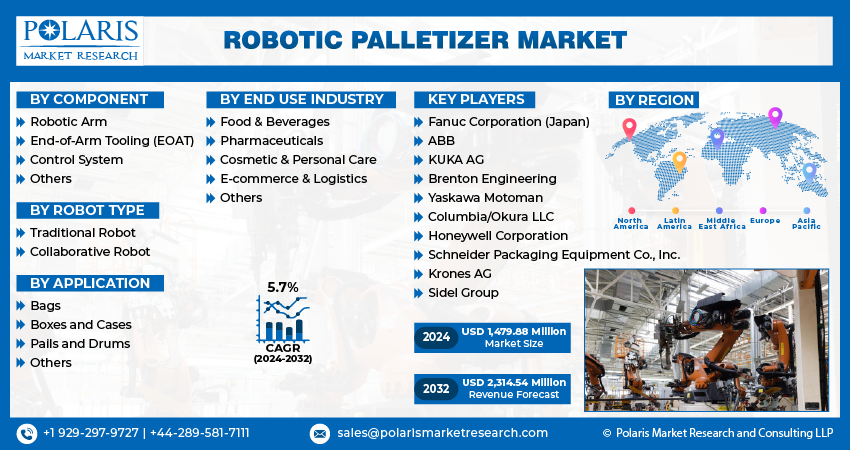

The global robotic palletizer market size is expected to reach USD 2,314.54 million by 2032, exhibiting the CAGR of 5.7% during the forecast period.

Market Overview:

A robotic arm is used by a robotic palletizer to pick, position, and orient individual products as they move from one place to another and then arrange them into a single load stack. The next generation of palletizers, known as robotic palletizers, is expected to take the place of regular palletizers eventually. These palletizers are recommended because of their many benefits, which include their adaptability, inexpensive initial investment, and capacity for multitasking.

Download Free Sample PDF Copy of the Report:

https://www.polarismarketresearch.com/industry-analysis/robotic-palletizer-market/request-for-sample

Major Players:

Prominent companies in the worldwide market place a strong emphasis on strategic acquisitions as a means of bolstering their R&D capabilities and gaining a competitive edge that will enable them to offer users cutting-edge products. The report has covered the major players operating in the robotic palletizer market:

- Fanuc Corporation (Japan)

- ABB

- KUKA AG

- Brenton Engineering

- Schneider Packaging Equipment Co., Inc.

- Yaskawa Motoman

- Columbia/Okura LLC

- Honeywell Corporation

- Krones AG

- Sidel Group

Growth Drivers:

Robotic palletizers improve operational efficiency by automating repetitive and physically demanding tasks, leading to increased throughput and lower operational costs. Automation ensures consistent palletizing patterns and accuracy, reducing errors in comparison to guide management. Scaling up or down robotic palletizers to meet production demands is a simple process.

Regional Analysis:

Robotic Palletizer Market, Regional Outlook (Revenue – USD Million, 2019-2032)

- North America

- Component Outlook

- Robotic Arm

- End-of-Arm Tooling (EOAT)

- Control System

- Others

- Application Outlook

- Bags

- Boxes and Cases

- Pails and Drums

- Others

- Robot Type Outlook

- Traditional Robot

- Articulated Robot

- Cartesian Robot

- Scara

- Collaborative Robot

- Traditional Robot

- End Use Industry Outlook

- Food & Beverages

- Pharmaceuticals

- Cosmetic & Personal Care

- E-commerce & Logistics

- Others

- Component Outlook

Recent Developments in the Robotics Industry:

- Yaskawa’s MOTOMAN-HC30PL (April 2019)

Yaskawa introduced the MOTOMAN-HC30PL, a human collaborative robot (cobot) designed for palletizing applications. The robot offers a payload capacity of nearly 30 kg, making it suitable for tasks that require both strength and safety when working alongside human operators. This development reflects Yaskawa’s ongoing efforts to enhance automation in industries such as logistics and manufacturing, where collaborative robots can improve efficiency and safety.

The robotic palletizer market is witnessing robust growth driven by several key factors. As industries increasingly adopt automation solutions to enhance efficiency and productivity, robotic palletizers emerge as a preferred choice for palletizing tasks. These systems offer speed, precision, and versatility, enabling seamless handling of various product types and packaging configurations. Additionally, the growing demand for warehouse optimization and logistics automation further propels the adoption of robotic palletizers. With advancements in robotic technology, such as AI-driven machine learning algorithms and collaborative robot designs, the market continues to expand rapidly. Moreover, the need for labor-saving solutions amidst rising labor costs and workforce shortages accelerates the uptake of robotic palletizers across industries.