Market Overview

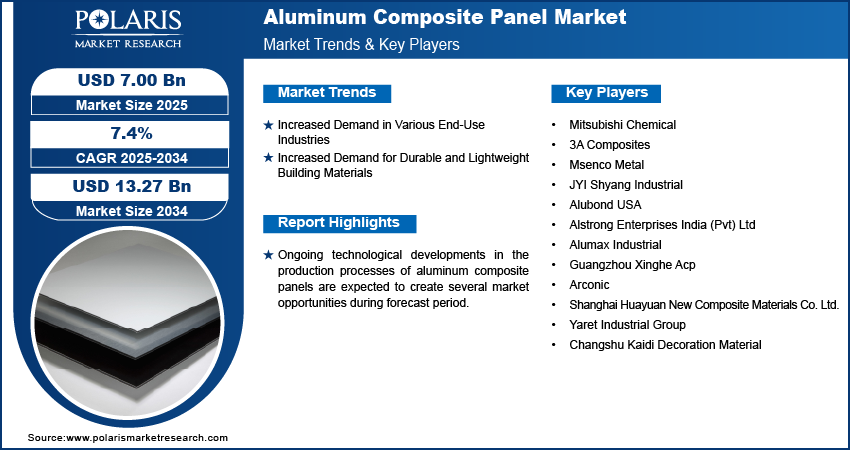

The global aluminum composite panel market is currently valued at USD 6.53 billion in 2024 and is projected to reach approximately USD 13.27 billion by 2034, according to the latest report by Polaris Market Research. The study highlights that the market is expected to grow at a strong Compound Annual Growth Rate (CAGR) of 7.4% over the forecast period from 2025 to 2034.

Aluminum composite panels (ACPs) are flat panels consisting of two thin aluminum sheets bonded to a non-aluminum core, typically made of polyethylene (PE), fire-retardant (FR) material, or a mineral core. Known for their lightweight nature, flexibility, and superior durability, ACPs are widely used in architectural cladding, interior design, advertising signage, and vehicle body panels.

Their ability to withstand harsh weather conditions, resist corrosion, and offer a wide range of surface finishes makes them a go-to solution for architects and designers looking to enhance building aesthetics and functionality. In addition, ACPs are relatively easy to install and maintain, further supporting their growing adoption.

LSI Keywords:

-

Architectural cladding

-

Fire-retardant panels

-

Facade systems

-

Building envelope solutions

Key Market Growth Drivers

1. Booming Construction and Infrastructure Sector

One of the primary drivers of the ACP market is the rapid expansion of the global construction industry. Urbanization, coupled with increasing investment in residential, commercial, and industrial infrastructure projects—particularly in emerging economies—has spurred demand for advanced and cost-effective building materials. Governments across Asia-Pacific, the Middle East, and Latin America are heavily investing in smart city projects and modern infrastructure, where ACPs are frequently used in facade systems and external cladding for their visual appeal and performance.

2. Sustainability and Energy Efficiency Trends

Growing emphasis on green building practices and energy-efficient construction materials is boosting the adoption of building envelope solutions like aluminum composite panels. ACPs help regulate indoor temperatures and reduce energy consumption due to their thermal insulation properties. Furthermore, eco-conscious manufacturers are innovating with recyclable aluminum panels and low-emission core materials, aligning with global sustainability goals.

3. Advancements in Panel Technology and Design

Manufacturers are continuously investing in research and development to enhance the performance and aesthetics of ACPs. Technological advancements have led to the introduction of fire-retardant panels, UV-resistant coatings, anti-bacterial surfaces, and self-cleaning options—broadening their application across diverse environments, including healthcare, airports, transportation hubs, and hospitality venues.

4. Growing Demand for Renovation and Refurbishment

Aging infrastructure in developed economies like the U.S., Germany, and Japan has led to a rise in renovation and retrofit projects. ACPs offer a cost-effective solution for upgrading the visual appearance and safety of existing structures. Lightweight and easy-to-handle properties make them ideal for over-cladding without significantly altering the structural load.

Market Challenges

Despite its strong growth prospects, the aluminum composite panel market faces several challenges:

-

Fire Safety Concerns: Traditional PE-core ACPs have been associated with fire hazards in several high-profile incidents globally, prompting stricter fire safety regulations and building codes. This has increased demand for fire-retardant panels, but also raised concerns about product compliance and cost.

-

Fluctuating Raw Material Prices: The price volatility of aluminum, a key raw material, impacts manufacturing costs and profit margins. This can deter smaller players and increase product prices for end-users.

-

Environmental Concerns and Recycling Limitations: While aluminum is recyclable, the composite nature of ACPs can complicate the recycling process, especially when bonded with polyethylene cores. There is a growing push toward sustainable materials that are fully recyclable or biodegradable.

-

Intense Market Competition: The presence of numerous global and regional players has led to pricing pressures. Continuous innovation and quality differentiation are critical to staying competitive.

Regional Analysis

Asia Pacific

Asia Pacific dominates the global ACP market and is expected to maintain its leadership over the forecast period. The region’s rapid urbanization, population growth, and infrastructural investments in countries like China, India, Indonesia, and Vietnam drive substantial demand for ACPs. Additionally, the booming commercial real estate sector and growing adoption of modern architectural cladding systems fuel regional growth.

North America

North America represents a mature market, with steady demand supported by renovation projects and sustainable building initiatives. The U.S. and Canada are focusing on improving energy efficiency and building safety standards, which is spurring demand for advanced and fire-retardant panels.

Europe

Europe holds a significant share in the ACP market, thanks to stringent regulations related to building safety and energy performance. Countries like Germany, the UK, and France are investing in green buildings, retrofitting, and urban renewal projects, driving demand for high-performance cladding and building envelope solutions.

Middle East and Africa (MEA)

MEA is emerging as a high-potential market with large-scale construction projects, including commercial complexes, hotels, and cultural landmarks in the UAE, Saudi Arabia, and Qatar. The demand for decorative and functional façade solutions is driving the uptake of ACPs in this region.

Latin America

While still developing, Latin America presents opportunities for market growth, particularly in Brazil, Mexico, and Chile, where infrastructure modernization and architectural innovation are gaining momentum.

Key Companies in the Aluminum Composite Panel Market

The global aluminum composite panel market is moderately fragmented, with a mix of established multinational corporations and regional players. Key companies are focused on strategic mergers, technological advancements, capacity expansions, and eco-friendly product development to gain a competitive edge.

1. 3A Composites

A leading manufacturer known for its ALUCOBOND® brand, 3A Composites offers a wide range of architectural ACPs. The company emphasizes innovation, sustainability, and product versatility across multiple industries.

2. Arconic Corporation

Arconic provides high-performance aluminum products, including ACPs designed for enhanced safety and aesthetics. Their Reynobond® panels are widely used in modern architectural projects worldwide.

3. Mitsubishi Chemical Corporation

Through its ALPOLIC™ brand, Mitsubishi offers premium-quality ACPs with fire-resistant and eco-conscious options. The company focuses on delivering solutions tailored to stringent international building codes.

4. Yaret Industrial Group

One of China’s largest ACP manufacturers, Yaret exports to over 70 countries. Their product offerings cover both standard and high-end panel solutions for exterior and interior use.

5. Jyi Shyang Industrial Co., Ltd.

Known for its long-standing presence and quality offerings under the name EVA Bond, the company serves a global clientele with diverse ACP applications, including signage and industrial usage.

Other notable players in the market include Alstrong Enterprises, Alucoil (Grupo Alibérico), Interplast Co. Ltd., HuaYuan Aluminum Industry Co., Ltd., and Fitzpatrick Panels.

Future Outlook

As architectural trends evolve toward more sustainable, energy-efficient, and visually appealing structures, the aluminum composite panel market is set to expand further. The growing integration of smart building technologies, stringent fire safety codes, and urban development initiatives worldwide will continue to fuel demand for innovative ACP solutions.

Manufacturers that invest in eco-friendly product innovations, recyclable core technologies, and strategic collaborations with construction and real estate companies are likely to gain a competitive edge in the years to come.

Conclusion

The global aluminum composite panel market is on a strong growth trajectory, driven by construction booms, modernization efforts, and sustainability goals. As architects, engineers, and developers seek multifunctional materials that combine performance with design flexibility, ACPs stand out as a compelling solution for the built environment of the future.

More Trending Latest Reports By Polaris Market Research:

Non-Automotive Rubber Transmission Belts Market

Xerostomia Therapeutics Market

North America Robot Operating System Market