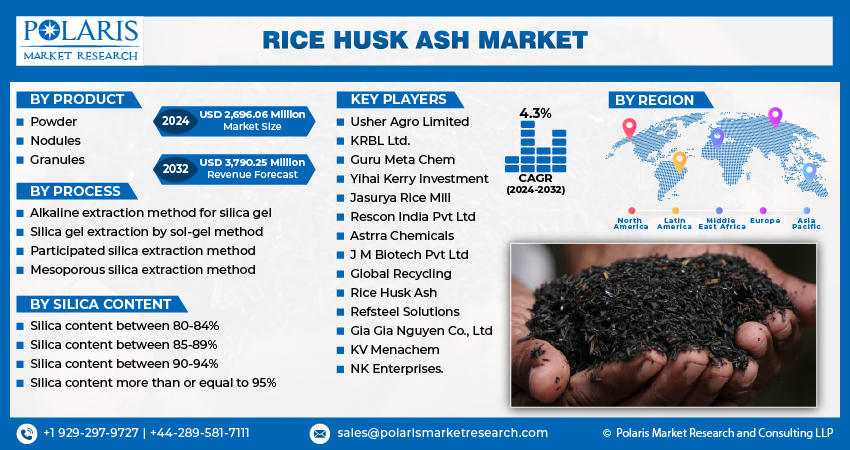

The global rice husk ash market is poised for steady growth as the world embraces sustainable and circular economy practices. Valued at USD 2,588.13 million in 2023, the market is projected to grow to USD 3,790.25 million by 2032, registering a CAGR of 4.3% during the forecast period, according to the latest market insights.

Rice husk ash (RHA), a biomass byproduct of burning rice husks for energy or heat, is rich in silica and has found growing application in cement, construction materials, steel, rubber, and ceramics. With the global emphasis on reducing carbon footprints and increasing the use of green cement additives, RHA’s unique chemical composition and environmental benefits are unlocking new market opportunities.

Market Overview: A Versatile and Sustainable Byproduct

RHA is produced during the controlled combustion of rice husks, which constitute 20–25% of the total weight of harvested rice. Once considered agro-industrial waste, RHA is now recognized as a valuable resource due to its high amorphous silica content (85–95%), pozzolanic properties, and low carbon presence. These properties make it suitable for use in the cement and concrete industry as a substitute for silica fume or fly ash, as well as a filler in rubber and plastics manufacturing.

The versatility of RHA extends across diverse industries, including construction, steel, refractory materials, agriculture, and chemical manufacturing. As companies aim to reduce the use of non-renewable resources, RHA is gaining momentum as a rice husk silica solution aligned with environmental sustainability goals.

Key Market Drivers

- Rising Demand for Eco-Friendly Construction Materials

The construction industry is under increasing pressure to reduce its environmental impact. RHA’s pozzolanic activity enhances cement strength while lowering emissions associated with clinker production. As builders and developers pursue LEED certifications and other green building standards, the use of RHA as a green cement additive is gaining popularity across global markets.

- Circular Economy and Agricultural Waste Management

Growing rice-producing nations such as India, China, Vietnam, and Thailand generate massive quantities of rice husks. Converting this agro-industrial waste into valuable industrial input not only reduces waste but also contributes to sustainable agricultural practices and economic development.

- Emerging Industrial Applications

Beyond construction, RHA is used in steel foundries as insulation material, in rubber and plastic industries as a reinforcing filler, and in water purification systems for its adsorptive properties. The development of high-purity RHA for use in electronics and ceramics further broadens its market potential.

- Government Policies and Sustainability Initiatives

Government-backed initiatives promoting the use of industrial byproducts, sustainable construction materials, and renewable energy sources are encouraging manufacturers to integrate RHA into their processes. Carbon credit programs and waste-to-wealth policies are also stimulating interest in rice husk valorization.

Browse Full Insights:

https://www.polarismarketresearch.com/industry-analysis/rice-husk-ash-market

Market Challenges

Despite its promising applications, the RHA market faces several obstacles:

- Quality Variation: The quality of RHA can vary significantly depending on combustion methods, affecting its usability. Standardization of processing techniques is essential to ensure consistent silica content and performance across industries.

- Limited Awareness and Infrastructure: In some regions, especially in developing economies, awareness about the commercial uses of RHA is still low. Moreover, inadequate collection, processing, and transportation infrastructure can hinder market growth.

- Logistics and Storage Concerns: RHA is lightweight but bulky, posing storage and transportation challenges. These logistical hurdles can increase costs and limit access to remote markets.

Regional Insights

Asia Pacific dominates the rice husk ash market due to its high rice production volume and rising infrastructure development. However, North America and Europe are increasingly importing high-purity RHA for niche industrial applications.

- Asia Pacific: Countries such as India, China, Vietnam, and Thailand are key producers of RHA due to abundant rice production. The region is also witnessing increased adoption of RHA in construction and agriculture, fueled by government support for green building initiatives.

- North America: The U.S. and Canada are focusing on sustainable construction, boosting demand for eco-friendly cement additives such as RHA. Importers are sourcing high-quality RHA from Asia to serve industries ranging from concrete to polymers.

- Europe: Driven by strict environmental regulations and demand for low-emission building materials, Europe is emerging as a lucrative market for RHA. Research institutions and industries are exploring novel applications of rice husk silica in electronics and composites.

Segmentation:

Rice Husk Ash Market, Product Outlook (Revenue – USD Million, 2019-2032)

- Powder

- Nodules

- Granules

Rice Husk Ash Market, Process Outlook (Revenue – USD Million, 2019-2032)

- Alkaline extraction method for silica gel

- Silica gel extraction by sol-gel method

- Participated silica extraction method

- Mesoporous silica extraction method

Rice Husk Ash Market, Silica Content Outlook (Revenue – USD Million, 2019-2032)

- Silica content between 80-84%

- Silica content between 85-89%

- Silica content between 90-94%

- Silica content more than or equal to 95%

Key Companies in the Global Rice Husk Ash Market

Several manufacturers and recyclers are actively developing technologies to produce high-quality rice husk ash and commercialize its potential across various sectors. Key companies include:

- Usher Agro Limited

- KRBL Ltd.

- Guru Meta Chem

- Yihai Kerry Investment

- Jasurya Rice Mill

- Rescon India Pvt Ltd

- Astrra Chemicals

- J M Biotech Pvt Ltd

- Global Recycling

- Rice Husk Ash

- Refsteel Solutions

- Gia Gia Nguyen Co., Ltd

- KV Menachem

- NK Enterprises.

Emerging Trends and Opportunities

- Nano-Silica Extraction: Technological advancements in extracting nano-silica from RHA are opening new avenues in the electronics, paints, and battery industries. This segment is expected to gain traction in high-tech manufacturing markets.

- Bio-Based Polymers: RHA is being integrated into bio-based polymer composites as a sustainable filler, reducing reliance on synthetic additives and enhancing mechanical properties.

- Waste-to-Energy Projects: Companies are integrating RHA production into biomass byproductenergy facilities, creating dual revenue streams from power generation and ash commercialization.

- Carbon Credits and Environmental Certifications: Use of RHA in green construction and industrial processes contributes to carbon reduction goals, enabling companies to gain environmental certifications and incentives.

Conclusion: Sustainable Growth Rooted in Innovation and Resource Efficiency

The global rice husk ash market is well-positioned to expand steadily over the next decade, propelled by sustainability imperatives, circular economy models, and broad industrial applicability. From reducing cement emissions to enhancing the quality of rubber and ceramics, RHA is turning from agro-industrial waste into a prized material in the age of green innovation.

As key companies continue to invest in advanced processing and develop new applications, the future of the rice husk ash industry lies in high-purity, scalable, and cost-effective solutions that bridge agriculture, industry, and environmental stewardship.

More Trending Latest Reports By Polaris Market Research:

Testing, Inspection, and Certification Market

Inspection Management Software Market

Industrial Protective Clothing Market

Advanced Phase Change Materials Market